SICK: Quality Control Systems – Foreign Object Detection System

October 28, 2021

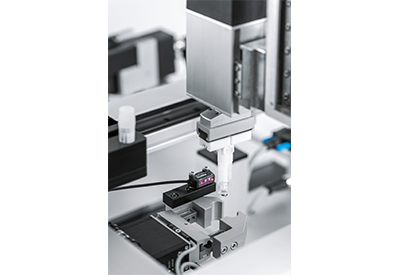

The Foreign Object Detection System quality control system detects foreign objects on simple surfaces, but also on demanding surfaces such as high-voltage batteries. The scalable system makes it possible to test a wide range of surfaces, regardless of their structure, texture and color. 3D cameras and the laser triangulation method ensure consistently high inspection quality. It maps surfaces three-dimensionally, thus detecting even the smallest foreign objects of the most varied shapes. In addition, customer-specific requirements can be integrated into the system, such as the detection of missing or incorrectly positioned screws.

At a glance

- – Optical testing system for foreign object detection based on the laser triangulation method

- – Scalable system setup with Ranger 3D vision cameras from SICK for 3D imaging

- – SICK AppSpace environment for customer-specific applications

- – Recipe management

- – Display for data visualization

Your Benefits

- – Detects very small foreign objects of various shapes, e.g. screws, nuts and tools

- – Reliable and accurate testing, even for challenging surfaces with different colors, structures and textures. Suitable for light, dark, smooth, ribbed, calotted, glossy, matte and other surfaces

- – No additional illumination required

- – Visualization of results

- – Additional detection tasks can be integrated, e.g. screw detection

- – Quick and easy change of test objects

Fields of applications

- – Optical testing system for foreign object detection based on the laser triangulation method

- – Scalable system setup with Ranger 3D vision cameras from SICK for 3D imaging

- – SICK AppSpace environment for customer-specific applications

- – Recipe management

- – Display for data visualization