Optimizing Liquid Cooling in Data Centers: Gems Sensors’ Role in Coolant Distribution Units (CDU)

January 22, 2025

As data centers continue to evolve to meet the demands of high-density computing workloads, liquid cooling has emerged as a game-changing technology. Offering improved thermal efficiency, reduced energy consumption, and the ability to handle increasing heat loads, liquid cooling systems are becoming indispensable for next-generation data centers. At the heart of many liquid cooling implementations is the Coolant Distribution Unit (CDU), a critical component that ensures efficient coolant management. Gems Sensors provides innovative solutions to optimize CDU performance, offering reliable sensing technologies for level, pressure, flow, and valve control.

Overview of Liquid Cooling in Data Centers

Traditional air-cooling methods struggle to keep pace with the growing heat loads generated by high-performance computing (HPC), artificial intelligence (AI), and machine learning (ML) workloads. Liquid cooling—including direct-to-chip cooling systems—delivers higher heat transfer efficiency compared to air cooling, enabling data centers to operate at higher densities and with greater sustainability. Coolant Distribution Units (CDUs) are essential to the operation of these liquid cooling systems, providing centralized management of coolant flow and thermal transfer to maintain optimal performance.

What is a Coolant Distribution Unit (CDU)?

A Coolant Distribution Unit is a specialized component in liquid cooling systems responsible for distributing, monitoring, and controlling the coolant flow between the cooling infrastructure and the server racks. Key functions of a CDU include:

- Thermal Regulation: Ensuring that coolant temperatures remain within specified ranges to optimize heat transfer and protect hardware.

- Flow Management: Circulating coolant through pipes, pumps, and heat exchangers for consistent cooling performance.

- Monitoring and Diagnostics: Using sensors to measure critical parameters such as coolant level, pressure, flow rate, and temperature.

- Leak Detection: Identifying potential leaks to prevent equipment damage and downtime.

- Efficiency Optimization: Managing energy use by controlling pumps and flow rates based on real-time data.

Gems Sensors Solutions for CDUs

To support the growing adoption of liquid cooling, Gems Sensors offers a comprehensive portfolio of sensing solutions tailored to the specific needs of CDUs. These include:

Level Sensors

Maintaining proper coolant levels is essential for uninterrupted CDU operation. Gems provides advanced level sensing technologies to ensure accurate monitoring and control:

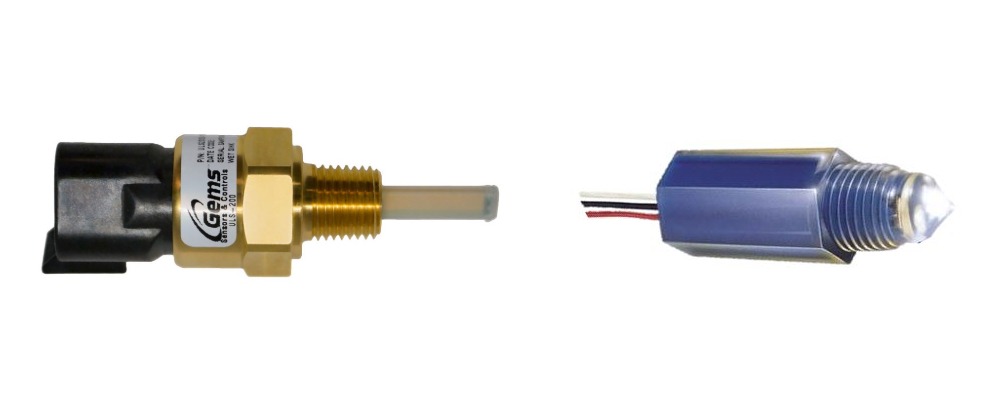

- ULS-200 Ultrasonic Level Sensors: Designed for direct contact measurements, these sensors provide reliable liquid level monitoring in coolant reservoirs and coolant manifolds to ensure all servers receive adequate cooling.

- ELS-1100 Electro-Optic Level Sensors: Compact and robust, these sensors are designed to detect high or low liquid levels, offering reliable performance in challenging environments.

Pressure Sensors

Pressure monitoring is vital to prevent system malfunctions caused by blockages or leaks. Gems’ pressure sensors provide high accuracy and durability:

- 3100 Series Pressure Transducers: These rugged sensors measure system pressure to detect abnormalities, ensuring coolant flows optimally through the system.

- 3500 Series Pressure Transducers: Designed for precise and reliable pressure monitoring, these sensors are ideal for maintaining system integrity in CDUs.

Flow Sensors

Effective coolant circulation depends on accurate flow measurement. Gems’ flow sensors help maintain consistent performance:

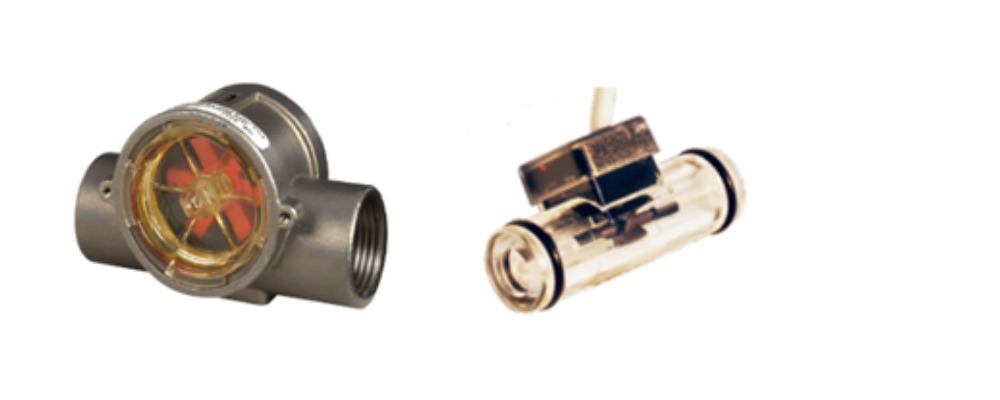

- Rotorflow® Flow Sensors: Featuring a visual indication of flow rate, these sensors provide precise flow measurement and monitoring in real-time.

- FT-110 Series Flow Sensors: Designed for high-accuracy flow measurement in liquid cooling loops, these sensors support efficient thermal management.

Valve Solutions

Controlling the flow of coolant through various sections of the system is critical to CDU functionality. Gems’ solenoid valves provide precise and reliable flow control:

- Gems’ AG and BG Series Solenoid Valves: Designed for high flow rates and fast response times, these valves ensure efficient coolant distribution within the CDU.

Why Choose Gems Sensors for CDUs?

As data centers adopt liquid cooling to manage increasing heat loads and improve energy efficiency, Coolant Distribution Units play a pivotal role in ensuring system reliability and performance. Gems Sensors’ innovative solutions for level, pressure, flow, and valve control empower CDU manufacturers and data center operators to achieve new levels of operational excellence. By choosing Gems Sensors, you’re not just investing in sensors—you’re investing in the future of efficient, sustainable, and high-performance data centers.

See their data center air-cooled HVAC and differential pressure solutions with Setra Systems here: Solutions Built for Data Centers

Also, read more on their Hybrid Cooling Solutions here: Hybrid Cooling in Data Centers: Enhancing Efficiency with Gems Sensors

Related Story

Proax Technologies Ltd. Now Authorized Distributor of Gems Sensors

Proax Technologies Ltd. is pleased to announce they are now an authorized distributor of Gems Sensors & Controls, a global supplier of sensing and control solutions. This addition aligns with their current offerings and will be available to all their clients throughout Canada, coast to coast. They are eager to show you the features and value-add of this new specialized partner; their internal staff will be available shortly for virtual presentations and informational calls.