Introducing the SMC D-MPG Series: Advanced Position Sensing for Compact Actuators

March 6, 2025

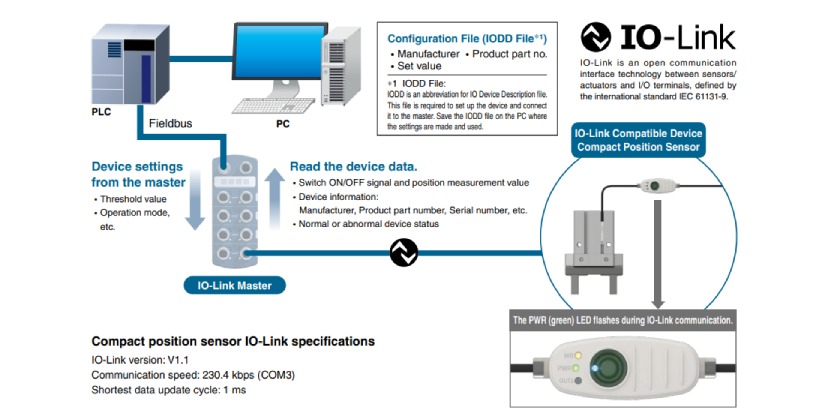

The new SMC D-MPG Series compact position sensors offer precision detection of stroke position in compact actuators such as air grippers. With impressive 0.1mm repeatability and IO-Link compatibility, these sensors provide versatile positioning solutions for automation applications.

Key Features and Benefits

Precise Position Detection

- High Repeatability: Achieves 0.1mm repeatability for reliable position detection

- Measurement Range: 25mm standard range (expandable up to 35mm)

- Resolution: 0.01mm for precise measurements

Compact, Versatile Design

- Two-Component System: Compact sensor head with separate teach unit

- Flexible Mounting: Can be mounted horizontally or vertically in standard cylinder grooves

- Compatible with Multiple Actuators: Works with various air gripper series including MHZ2, MHS3, MHK2, and more

Multiple Output Options

- Switch Output: Four selectable modes (Single-point, Auto Switch, Window, and 2-Point)

- Analog Output: Configurable voltage (0-10V, 1-5V) or current (4-20mA) output

- IO-Link Compatible: Digital communication for advanced control and monitoring

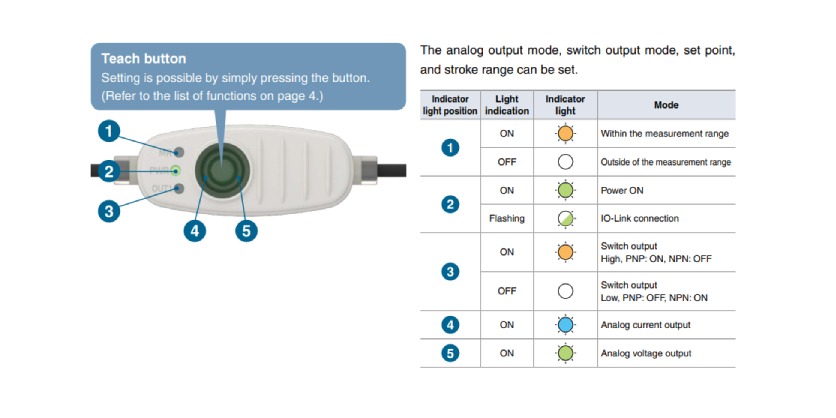

Easy Setup and Configuration

- Simple Teach Button: Quick configuration with a single button

- Visual Indicators: Five indicator lights show operational status

- Customizable Range: Adjustable measurement range and output settings

Industrial-Grade Reliability

- IP67 Rated: Protected against dust and temporary immersion in water

- Robust Construction: 300 m/s² impact resistance

- Wide Temperature Range: Operates from -10°C to 60°C

Applications

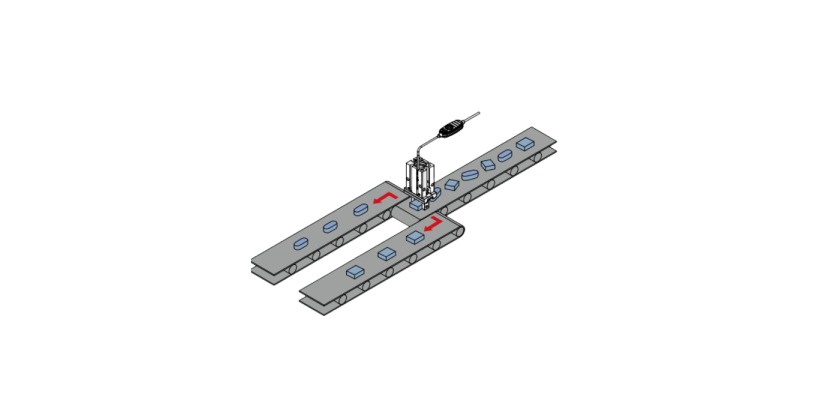

The D-MPG Series is ideal for applications requiring precise positioning of compact actuators, including:

- Part presence/absence detection

- Workpiece dimension verification

- Position-based sorting operations

- Precision assembly processes

- Multi-point detection sequences

With its ability to detect stroke positions with high accuracy, the D-MPG Series helps manufacturers improve quality control, reduce setup time, and enhance automation flexibility.

Elite SMC Distribution and Support from Proax

As an elite SMC distributor across Canada, Proax Technologies provides unparalleled expertise and support for the D-MPG Series and the complete SMC product line. With 13 locations nationwide, their team of in-house engineers offers comprehensive technical assistance, from product selection to implementation and troubleshooting.

Proax’s technical capabilities include:

- Application-specific product recommendations

- System integration support

- Custom automation solutions

- On-site consultations

- Training and education

- Ongoing technical support

Whether you’re upgrading existing equipment or designing new automation systems, Proax’s engineering team can help you maximize the benefits of SMC’s innovative position sensing technology.

More Information

For more information about the SMC D-MPG Series compact position sensors, connect with their technical team.

Related Story

SMC ZGS Vacuum Gripper System: An All-in-One Solution for Automated Handling

Modern manufacturing and logistics sectors demand increasingly efficient and reliable automation solutions, especially when it comes to handling delicate or irregularly shaped items. Available through Proax, SMC’s elite distributor, the ZGS Vacuum Gripper System (Foam Type) represents a significant advancement in this field, offering a comprehensive solution for palletizing and depalletizing applications, particularly for corrugated cardboard and similar materials.