Three Reasons Why You Should Visit an Omron Proof of Concept Centres

February 15, 2022

Omron knows that innovation works best when people bounce ideas off each other and develop a familiarity with building-block technologies and concepts. That is why Omron has decided to invest in state-of-the-art proof-of-concept centres (PoCCs) that house a multitude of Omron products, demos, testing equipment, and more. There are 29 Omron PoCCs around the globe, with several strategically located throughout the Americas. Omron strives to make each PoCC as accessible as possible, as they understand that automation solutions are a major investment and potential customers want proof that they will work as promised.

This article will look at three key benefits of visiting an Omron PoCC.

1. You’ll build your own expertise in a collaborative space.

If you’re in need of a spot to generate ideas with the guidance of Omron experts and gain a thorough understanding of our technologies, look no further than your local Omron PoCC. We’ve designed these facilities to serve as innovation spaces for collaboration with our partners, our customers, and our customers’ customers.

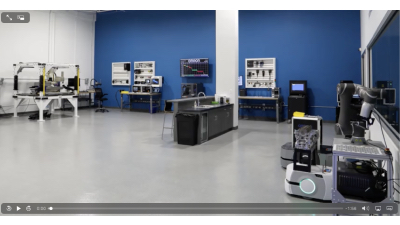

You’ll get hands-on access to technologies and demo applications that may include complete Sysmac platform solutions, integrated multi-robot systems, collaborative robot bin picking systems, traceability technologies, machine safety solutions, and much more. As each PoCC grows, you’ll find even more Omron products and solutions on display.

2. You’ll get access to high-quality training from the experts.

Each center is home to many specialized engineers with years or even decades of experience. If you’ve been wanting to chat with the experts at your own convenience, this is the best way to do so. Our engineers are ready to offer advice on your latest applications either in person or virtually. Some centers, like the one in Cincinnati, feature dedicated training rooms.

We’re always eager to learn more about your goals so that we can offer creative ways to solve application challenges. If necessary, our experts can connect you with Omron’s worldwide network of field applications engineers that have wide-ranging expertise in vision, safety, robotics and more.

3. You’ll get proof that your next solution will work, prior to implementation.

In each location, you can see real working applications that incorporate our latest technologies. It’s exciting to see such high-performance demos in a working environment and interact with experts. If you’re at the early stages of your automation investment, we’ll listen to your challenges and try to propose a solution that will sharpen your competitive edge.

Feasibility studies are offered in several facilities for advanced sensing technologies, and some centers have additional laboratories for specialized testing. The Detroit PoCC, for example, has an in-house vision lab where application engineers bring in parts and test out any applications – particularly vision and sensing applications – that require controlled lighting.

Our goal is to help customers minimize risk by validating their solutions prior to implementation. Once you see how Omron technologies can help solve your applications, we’ll help you follow up with our field application engineers.

Want to see what’s offered at the PoCC nearest to you?

To see the complete listing of all Omron Automation Proof-of-Concept Centres, click here