Cobots by UR Help Manufacturers to Overcome the Labour Shortage

February 6, 2023

Universal Robots (UR) is on the cutting edge with its industrial automation solutions, particularly collaborative robot arms (or “cobots”), which are available from Advanced Motion & Controls Ltd. A major benefit of UR cobots is their ability to fill urgent labour gaps, especially during the current international labour crisis.

With worldwide industry handicapped by a shortage of skilled labour, UR can help by automating difficult, repetitive processes while moving current employees to more rewarding positions.

Complicated challenge to overcome

The lack of skilled workers is a complicated challenge that needs to be overcome. This crisis has affected manufacturers for years, especially in Europe, where three out of four companies reported having difficulty finding the right workers in 2019. No improvement is currently in sight, so businesses and other decision makers must collectively care for the workforce, since people are the most important economical resource.

A variety of factors has led to this insufficient worldwide labour supply. First, the population of Boomers is getting older and retiring earlier, while fewer young people are entering the labour market. In the United Kingdom alone, this changing demographic is causing the largest shortage of skilled workers since 1989. Second, countries need to find new ways to attract external labour. Getting skilled workers to apply for high-demand fields is a long-term issue, but many companies have immediate requirements.

Businesses today need to rethink their policies and workplace culture to appear more attractive to potential employees. For example, salary is no longer the main determining factor for many young people, who are more interested in engaging work, remote options, flexible hours, and better work-life balance. Finally, manufacturers must consistently invest in developing and expanding new technologies. The current digitization of manufacturing processes favours automation; even partial automation cushions the effects of demographic change, boosts efficiency and reliability, and enables production at full capacity.

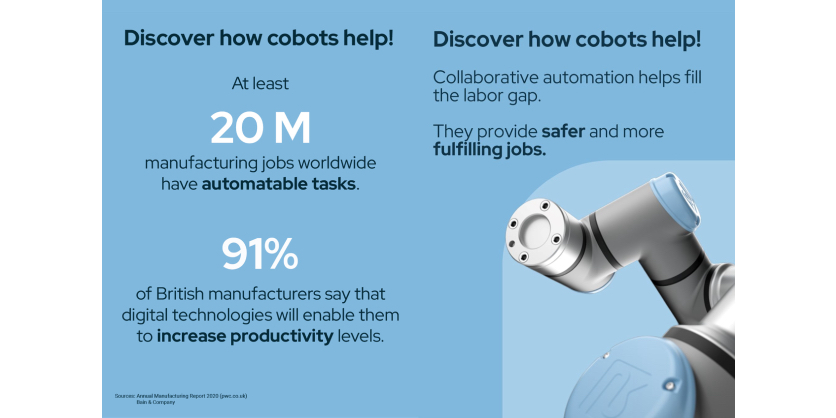

Advanced Motion & Controls can deliver UR cobots quickly to fill these urgent labour gaps. At least 20 million manufacturing positions worldwide have automatable tasks, allowing existing workers to move to safer, more fulfilling jobs.

More Information

Contact Advanced Motion & Controls

Related Story

We’re Ready When You Are. Universal Robots

By overcoming global supply chain issues through its approach to component sourcing and manufacturing, Universal Robots is currently able to ship orders in just two weeks. One of the shortest lead times in the market. But why is delivery time important for customers and partners? We asked some UR country managers for their perspectives.

When you look at the reasons customers turn to cobots, it becomes clear why delivery time matters. Though there are many good reasons for automating, sometimes cobots are chosen as a solution to real and immediate problems such as manufacturing labor shortages. It makes sense that the sooner businesses are able to tackle these obstacles, the better the outcome will be.