Key to the Comprehensive SCHUNK Chuck Jaw Portfolio

February 12, 2024

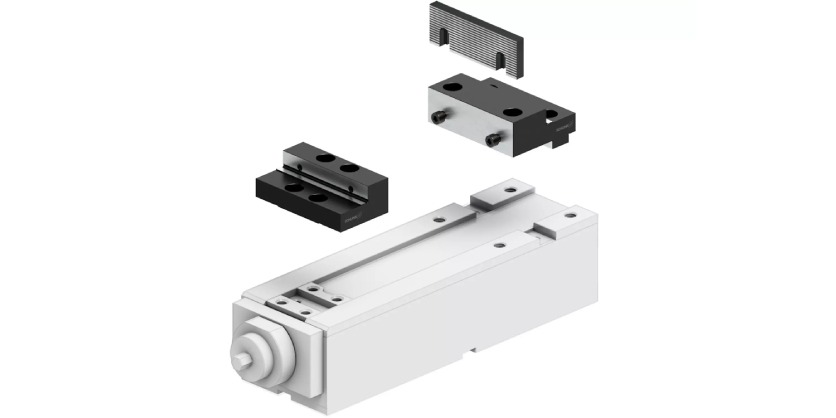

With new adapter jaws, SCHUNK has established compatibility between machine vises and the world’s broadest portfolio of top jaws from SCHUNK/GRESSEL. These useful connecting elements offer new and flexible clamping options for any machining task

The interface between the machine vise and the top jaws for the specific clamping task depends on the manufacturer. Until now, users have been bound to the respective vise manufacturer’s jaw portfolio for this reason. This is now a thing of the past with the new SCHUNK adapter jaws. They enable SCHUNK to create compatibility between the vise and its top jaw portfolio, which is the most extensive on the market worldwide. Therefore, users are no longer tied to a specific system, but can now significantly expand their clamping options.

Fast amortization due to a more favorable top jaw portfolio

The potential of the adapter jaws for machine vises with a jaw width of 125 mm is considerable. This is because they offer concrete advantages for stationary workpiece clamping on vises, especially in milling machines:

The SCHUNK adapter jaws open up any top jaw variation for virtually infinite clamping possibilities. Due to this flexibility, many different clamping options can be achieved – not to mention the cost advantages. After the initial investment for the adapter jaws, this expenditure can be amortized very quickly by using the top jaws from the SCHUNK jaw portfolio, since the top jaws are less expensive than comparable competitor products. Another advantage is the set-up time savings and process optimization due to the quick-change function on some variants of the top jaws from the SCHUNK jaw portfolio. Screws only have to be loosened slightly instead of completely, and the jaw can be easily removed upwards along the grooves.

Depending on the workpiece and application, different top jaws are mounted on the adapter jaws for the respective clamping task. The customer can continue to use its original system jaws, which results in greater cost-effectiveness. Logistics and process planning also become easier – another plus point for users, because thanks to the adapter jaws, the same top jaws can be used on different vises. This also provides a sustainability benefit, as existing products can be reused. And finally, the short delivery times will certainly impress users, as they can access the standard portfolio of SCHUNK top jaws instead of having to wait for products in special design.

Plug & Work – with no additional interface

This is how the SCHUNK adapter jaws turn third-party vises into “partners” for any clamping application, as they create a useful and flexible connection. Now the extensive range of adapter jaws fits vises from market players such as Allmatic, Roemheld or Röhm, for example. Replacing previous system jaws in the vise is done quick and easy – the new SCHUNK adapter jaws can be replaced one-to-one and are instantly ready to use due to the easy handling – just mount them and get started. No other interfaces are required.

More Information

Related Story

Find Your WOW Effect with Your Tailored Clamping Technology for Your Application Areas from SCHUNK

Surprisingly versatile: VERO-S NSE3. Pull-down force and the high dimensional stability of the module body. Therefore, very high tilting moments and lateral forces can be absorbed by the modules. This module can be expanded with a variety of different equipment.