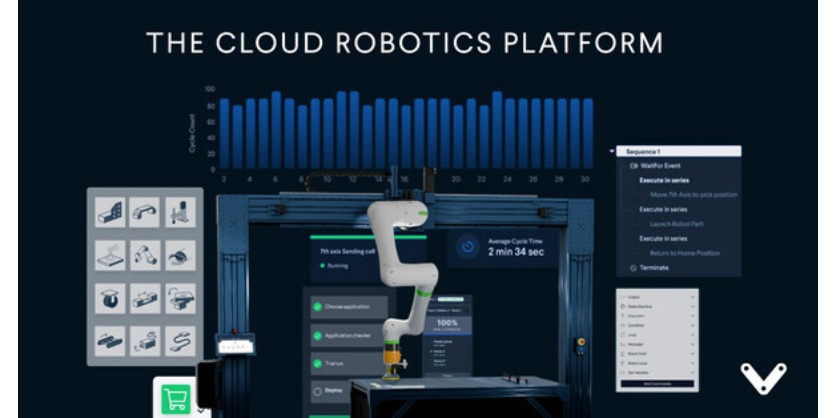

Vention Launches New Cloud-Robotics and AI Capabilities to Accelerate the Design and Deployment of Robot Cells

July 18, 2024

Further enhancing the ease of designing, programming, and deploying robot cells while also equipping advanced users with more powerful programming tools.

Vention, the cloud robotics company, has released a suite of AI-powered capabilities to its Manufacturing Automation Platform (MAP). These new capabilities, available immediately to the more than 4,000 manufacturers already using Vention, strengthen the company’s position as the only end-to-end platform to design, automate, order, deploy and operate automated equipment and robot cells in the cloud.

MachineBuilder capabilities enhanced for robot cell design

The latest version of MachineBuilder, Vention’s cloud-based 3D design software, brings forward the most comprehensive suite of enhancements over the past 36 months with more intuitive and smarter design tools.

Specific product capabilities include:

- Streamlined design flow: Empowers teams to work faster and more confidently with hundreds of machine design templates.

- Smarter part placement: Minimizes the effort of creating mechanical structures when designing in 3D. Powered by Vention’s AI-driven Geometric Reasoning Engine (GRE), components added to a design automatically snap to the desired orientation with minimal user input.

- Enhanced part manipulation: Reduces the learning curve of designing in MachineBuilder with new part manipulation tools powered by contextual guidance and a more discoverable 3D manipulator.

- Real-time design and part specifications: Increases visibility into part and design specifications with real-time updates as components are added to the bill of material. Technical specifications, 2D drawings and more are now directly available in the 3D design environment.

Robotic programming capabilities pave the way for complex cloud applications

The release of Vention’s MachineLogic new code-free programming instructions further simplifies how users program robot arms and all adjacent devices in a robotic cell. Combined with the new scene asset functionality, developers can leverage their digital twin to accelerate the deployment process. Users can now program their robot in the cloud and deploy it directly to the factory floor.

Specific product capabilities include:

- Point and click robot programming: Inserts waypoints and reference frames easily into a digital twin. Enables developers to visualize the position of reference frames and waypoints in the scene using new scene widgets.

- Extensible workflows and powerful authoring capabilities: Defines parametric reference frames and waypoints with variables and expressions.

- Calibration Frame: Defines calibration frames in your digital twin to enable the level of precision required for your robotic application.

Instantly and securely deploy robot cells from the cloud to the factory floor

The inclusion of a new instant deployment functionality empowers robotic developers to transfer programs and machine configurations from a digital twin to a physical machine directly in the web browser. This new feature integrates with Vention’s ISO 27001 and NIST-800-171 certified MachineCloud infrastructure, expediting deployment processes and facilitating a seamless redeployment from the digital twin to the real world without disrupting production.

Enhanced user interface authoring added to the cloud robotics platform

Vention adds web development tools and workflows to its cloud-based robot programming platform, enabling advanced users to create and simulate robot applications that contain feature-rich operator interfaces. This new release confirms Vention’s commitment to providing an extensible platform that strives to meet the robotics industry’s and its practitioners’ evolving needs.

In addition, as a continuation of its commitment to the needs of its industry, Vention will publish the second edition of its State of DIY Industrial Automation Report on May 6. Following its success in 2023, the company has decided to survey their clients again to understand better the trends unveiled last year, such as the emergence of Advanced Manufacturing Teams, the importance of platforming industrial automation and the preference for self-service and self-design.

Quote

“Those releases are all about the intersection of robotics and AI-driven design capabilities. Unlike traditional 3D design and offline programming software, Vention’s Manufacturing Automation Platform is poised to leverage AI to simplify the design-to-deployment experience. With a dataset comprising over 365,000 automated equipment and robotic cell designs, each labeled with rich geometric data and metadata, and continuous investment in Vention’s Geometric Reasoning Engine and Graph Neural Networks, the task of designing, automating, ordering, deploying, and operating robotic cells in the cloud has never been more seamless. And this is just the beginning.” – Etienne Lacroix, founder and chief executive officer, Vention.

More information at Automate 2024

From May 6 to 9, visit Vention’s booth No.2813 to see six machines in action and attend software demos and educational animations.

Company Founder and CEO Etienne Lacroix will speak twice on May 6:

- 11:15 a.m. to noon: Room S401cd – “The Rise of the Advanced Manufacturing Team and DIY Industrial Automation”

- 1:45 – 2:45 p.m.: Automate Show Theater – Panel Discussion: “How Ease-of-Use Automation is Empowering Industries”

About Vention

Vention helps some of the most innovative manufacturers automate their production floors in just a few days through a democratized user experience. Vention’s manufacturing automation platform allows clients to design, automate, deploy and operate automated equipment directly from their web browsers. Headquartered in Montreal, Canada, with one office in Berlin, Vention’s 300 employees serve 4,000+ customers in five continents and across 25 manufacturing industries.

More Information

For more information, visit vention.com or follow them on LinkedIn.

Related Story

Vention Announced as One of Deloitte’s Technology Fast 50™ Program Winners for 2023

Vention, a leading digital manufacturing automation platform (MAP), was recognized for the third time as part of the 2023 Deloitte Technology Fast 50™ awards program for its rapid revenue growth, entrepreneurial spirit, and bold innovation.