Sonair to Debut World’s First Safe 3D Ultrasonic Sensor for Autonomous Robots at Automate 2025′

May 9, 2025

‘ADAR’, an award-winning 3D ultrasonic sensor poised to challenge the dominance of LiDAR in robotics perception, will launch at Automate 2025, May 12-15 in Detroit, Michigan. The first orders are already in place and the groundbreaking sensor is on track to achieve safety certification, an industry-first for 3D ultrasonic sensing in air.

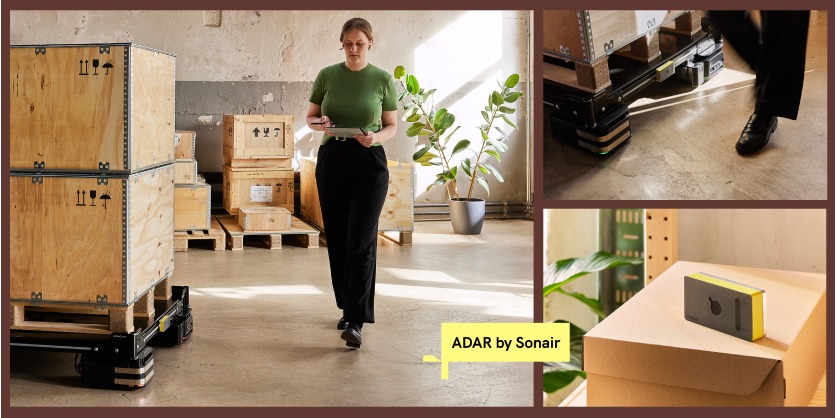

Sonair ADAR, claimed to be the world’s first safe 3D ultrasonic sensor designed to boost safety in spaces shared by humans and robots will debut to North American audiences May 12 at Automate 2025, one of the world’s leading automation trade shows.

Sonair, the Norwegian sensor firm behind the award-winning sensor, was selected from a crowded field of contenders to participate in the prestigious Automate Startup Challenge.

“Safety just got a lot simpler — and better adapted to detect people,” says Knut Sandven, CEO, Sonair. “ADAR enables 3D 360-degree obstacle detection around autonomous mobile robots (AMRs) at a significantly lower cost than the sensor packages used today, enabling AMR manufacturers to build safe and affordable autonomous robots.”

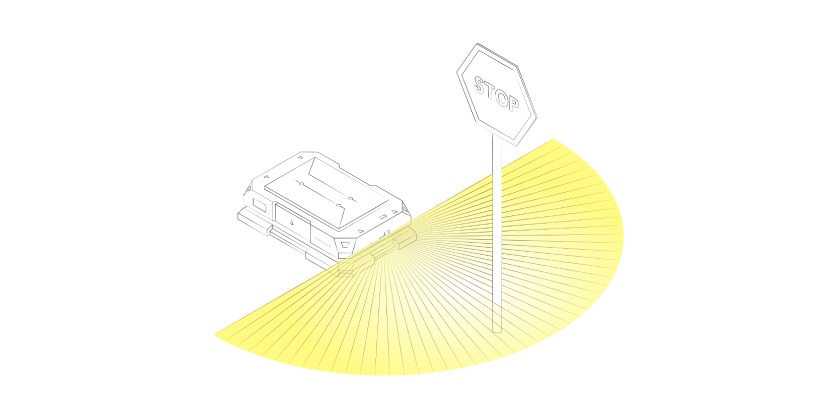

A typical 2D LiDAR safety scanner in an AMR only sees a person’s legs in one horizontal plane. In contrast, Sonair’s patented ADAR (acoustic detection and ranging) technology detects people and objects in 3D. A single ADAR sensor provides a full 180 x 180 field of view (FoV), and a 5 meters range, for the robot’s safety function.

The core technology behind ADAR has been in development at the world-renowned MiNaLab sensor and nanotechnology research center in Norway for more than twenty years. The imaging method is called beamforming; it’s the backbone of processing for SONAR and RADAR, as well as in medical ultrasound imaging, and now ready for ultrasound in-air applications.

Sonair is on track to achieve safety certification for ADAR by the end of 2025. This is an industry-first for 3D ultrasonic sensing in air.

At Sonair’s Automate booth #4710, attendees will experience first-hand how they can see themselves – and other objects – through soundwaves in the air.

Sensing validation

More than 20 global companies, including AMR manufacturers, industrial manufacturing conglomerates, automotive technology suppliers, and vendors within the autonomous health and cleaning industries, have quietly validated the Sonair ADAR sensor’s effectiveness as part of a successful Early Access Program launched in Summer 2024.

Commercial orders -and endorsements- are already flowing, including from Japan’s FUJI CORPORATION, which has procured ADAR for an upcoming line of autonomous mobile robots, and from a leading Swiss manufacturer of autonomous robots for the cleaning industry.

“Sonair combines rapid development capabilities with a flexible mindset,” says Koji Kawaguchi, General Manager of the Innovation Promotion Department, FUJI CORPORATION. “Thanks to their cooperation, through comprehensive testing we were able to confirm the high suitability of their sensors for autonomous mobile robots.”

“We see significant potential for Sonair’s ADAR technology in the Japanese robotics market, particularly in applications requiring reliable, safe human-robot interaction,” said Shuhei Monobe, Department Manager of Electronics Devices Department, Cornes Technologies, a distribution partner for Sonair. “Our early outreach has already generated confirmed interest from leading customers. As a novel approach to 3D sensing, ADAR offers compelling advantages in both performance and cost. We look forward to deepening our collaboration with Sonair and bringing this innovation to more of our clients.”

What is ADAR?

Acoustic detection and ranging (ADAR), a patented innovation by Sonair, is a new category of 3D depth sensor. It empowers autonomous robots with omnidirectional depth perception, enabling robots to “hear” their surroundings in real-time 3D – using airborne soundwaves to interpret spatial information.

ADAR is developed according to ISO13849:2023 performance level d/SIL2. The sensor creates a virtual safety shield with a range of 5 meters, that enables people and robots to share space safely. The innovation lies in combining wavelength-matched transducers with efficient signal processing for beamforming and object recognition algorithms.

“ADAR is an advanced plug-and-play sensing technology ensuring compliance with safety standards. With its small form factor, and low power and compute consumption, it is easy to integrate as part of a combined sensor package,” explains the Sonair CEO.“It takes the ‘uh oh’ out of human robot coexistence and replaces it with an ‘all clear.’”

Sonair ADAR is scheduled to be ready for shipment in July 2025.

To get a live demo or discuss your robotics use case, reach out to the Sonair team at hello@sonair.com or complete the form at sonair.com/contact

About Sonair

Sonair is an award-winning deep tech startup building a breakthrough, patented 3D ultrasonic sensor that enables true machine autonomy by making robots safe, affordable, and efficient. Sonair was spun out from a leading European independent research organization, SINTEF, to exploit deep science-to-tech advancements in ultrasonics and Micro-ElectroMechanical Systems (MEMS). Using this technology, the company is delivering a sensor that will transform a robot’s safety zone from 2D to 3D, offering a significantly improved safety performance over traditional vision systems while cutting costs significantly.

The company, based in Oslo, Norway, was founded in 2022 by an experienced team of serial entrepreneurs led by Knut Sandven, former CEO of GasSecure.

More Information

Learn more: www.sonair.com