Plan Robotic Cells More Easily With KUKA.Sim 4.0 Simulation Software

June 3, 2021

Digital planning of KUKA systems on a new level

The KUKA.Sim simulation software brings robot applications to life – even before the real system is put into operation. With the new version of KUKA.Sim 4.0, users now reach a new level of planning reliability, simplicity and cost efficiency. This means greater functionality and lower time requirement.

Greater planning reliability due to a vast range of options

Besides importing CAD data, the new version enables easy offline programming of the robot and fast cycle time analysis. In addition, safety spaces can be configured graphically in 3D and the stopping behavior of the robots can be simulated. “The total area required for the cell can thus be significantly reduced during planning,” says KUKA portfolio manager Roland Ritter.

KUKA.Sim 4.0 facilitates the planning of robot applications in many industries: from consumer goods to electronics and automotive – particularly for component suppliers. The new KUKA Robot Language (KRL) editor provides two user views for programming the robot: one for experts and one for beginners. A visual program tree makes programming possible even without KRL knowledge, for example. Users benefit from a new simplicity. The 100-percent data consistency also ensures that the virtual controller and the real controller work with the same data. The software now also supports the new KR SCARA and KR DELTA robots from KUKA.

Modular add-ons: save time, plan realistically

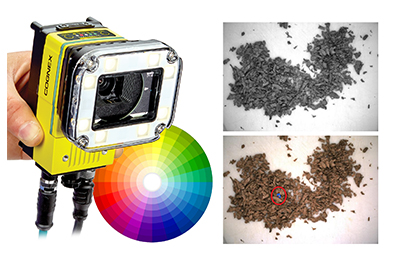

With the KUKA.Sim Modeling add-on, a customized component library can be created from your own CAD data – such as kinematic systems, sensors, material flow or physical behavior. The new Connectivity add-on allows users to commission the cell virtually. This creates a digital twin for greater planning reliability and the best possible implementation. For this, KUKA uses behavioral emulators such as WinMOD and SIMIT. With the Arc Welding add-on, users speed up their offline programming for welding applications: approach positions or the optimum orientation of the robot for the welding process can be defined, for example.

From a 2D drawing to a 3D view and back

The export possibilities with KUKA.Sim 4.0 are unbeatable. Integrators in particular benefit from this: they can export the simulation as a 3D PDF and the customer simply opens it with Acrobat Reader. Detailed information in 2D for mechanical commissioning can also be provided via the export feature. One of the highlights is product presentation using a virtual reality headset. Tablets and smartphones also deliver impressive simulation results on the go via the Mobile Viewer app. Interested parties can test the demo version free of charge for 30 days.

Digital planning of KUKA systems on a new level

The KUKA.Sim simulation software brings robot applications to life – even before the real system is put into operation. With the new version of KUKA.Sim 4.0, users now reach a new level of planning reliability, simplicity and cost efficiency. This means greater functionality and lower time requirement.