New G2RV-ST And G3RV-ST Relays from Omron

Omron’s New G2RV-ST And G3RV-ST Relays Are Among the Fastest in the Industry That Provide Better Visibility, Top-Notch Reliability, and Vibration Resistance

January 23, 2023

Speedier relays are a key requirement in today’s fast-paced manufacturing industry, and Omron responded to this need with the new ST relays that are among the fastest available on the market today.

Industry-leading automation solution provider Omron Automation Americas recently launched new G2RV-ST and G3RV-ST Slim Relays. These industry-leading switching speeds allow for use in a wider range of applications, including PLC outputs for heating applications and bottling lines.

In addition to their exceptional speeds, the G2RV-ST and G3RV-ST are notable for their slim dimensions that help customers reduce control panel footprint and their visual status indicators that make it easy to quickly confirm operation, voltage type, and relay condition.

Like other Push-In Plus technologies from Omron, the new relays are designed to resist vibration and hold wires firmly in place without the need for periodic re-tightening.

Key Features:

- Operate time of 0.2ms and release time of 0.4ms (for G3RV Solid State relay)

- 6.2mm width and uniform dimensions to optimize space usage

- Locking lever arm and secure relay socket enclosure

- Robust DIN attachment

- Short bar termination feedback

- Integrated circuit test button

Key Customer Benefits:

- Better space savings in the control panel. Omron panel solutions are designed with a uniform height, depth, and component spacing to optimize the space utilized, assuaging concerns about the size of control cabinets. In fact, Omron components can save anywhere between 20-50% space inside the panel, and the slim relays have a width of just 6.2mm.

- Improved usability. Omron slim relays are designed to improve the user experience with a simplified installation process and features that help identify relay status and operation. They also offer features like a locking lever arm, secure relay socket enclosure, larger wire terminals, robust DIN attachment, short bar termination feedback, and an integrated circuit test button make slim relays easier to provide greater value and usability.

- Excellent vibration resistance. Omron relays with Push-In Plus terminals are designed to resist vibration with a stronger hold on terminated wires, and they do not require any re-tightening over time.

- Better visibility for status indicators. Customers need to verify the function and status of a relay — and get other critical information about relay operation — with a quick visual check, so Omron relays are designed with visual status indicators that make it easy to confirm operation, voltage type, and relay condition.

Switching speeds that accommodate the fastest applications. Customers need faster relay switching performance to operate modern devices with PLC outputs. Omron relays have some of the lowest operate and release times in the industry, allowing for use in demanding situations that require fast switching, like PLC outputs for heating applications or a bottling line.

Target Customers:

The new G2RV-ST And G3RV-ST slim relays are ideal for customers who have the following applications and are seeking to optimize control panel space usage:

- Food processing machines (peeling/skinning stations)

- Packaging machinery

- Palletizers and de-palletizers

- Assembly lines

- Material handling systems

- Robotic cells

- Power-presses

- Body transfer lines

- Folding or brake presses

- Filter presses

- Punching machines

- Machine tending

- Printing machines

- Corrugating machines

More Information

Visit the G2RV-ST and G3RV-ST product pages

Related Story

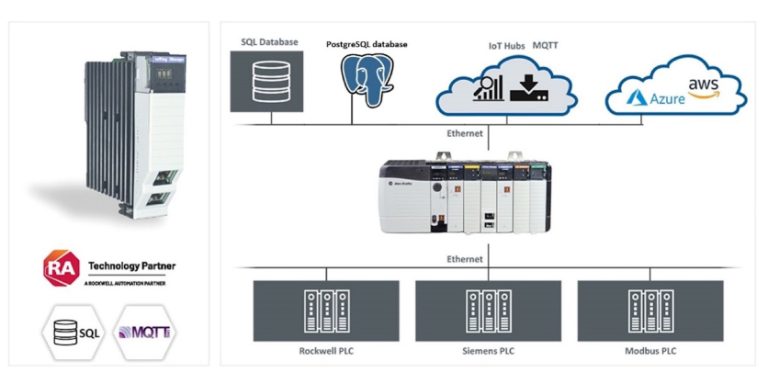

Seven Remote Access Problems That You Can Solve with Omron’s New IoT Gateway

As machines become more connected, the need to service equipment remotely is escalating. Production is often running 24/7 and manufacturers expect immediate action from machine specialists. Not having a remote solution creates challenges like high travel costs, whereas some remote solutions cause a loss of data control and increase vulnerability.

Omron’s secure remote access IoT gateway is one of the most advanced, turnkey solutions you will find on the market today, and it addresses multiple weak spots in competing solutions Omron looks at some of the concerns that this technology can help.