Direct Teach, Plug and Play Collaborative Robots Enhance Yaskawa’s HC-Series Line

March 17, 2022

Highly reliable, the six-axis HC10DTP and HC20DTP collaborative robots enrich easy capability for Yaskawa’s HC-series line. Hand-guided programming allows users to direct teach points without a pendant, and an ISO standard tool flange and electrical connections facilitate a plug and play approach for easy deployment of the robot system.

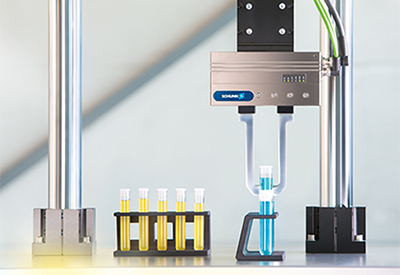

Ideal for a wide variety of collaborative applications including assembly, dispensing, machine tending, material handling, packaging and welding, the HC10DTP and HC20DTP enable humans to safely work with robots. Power and Force Limiting (PFL) technology constantly monitors force to quickly and safely react to contact, and advanced pinchless geometry provides the utmost safety. A thru-arm Category 6 Ethernet cable, I/O cable and dual air lines eliminate external utilities while offering fast, safe and easy setup of a wide variety of communication options for tooling.

Made of cast aluminum for durability, both robots are IP67-rated and equipped for use in damp or splash-prone environments. Each model features an easy-to-clean surface, allowing utilization in sanitary environments where wipe or wash is required. NSF H1 certified food-grade grease is included as standard, enabling use in settings where there is a possibility of incidental food contact.

Meeting established safety standards (ISO 13849-1) and complying to ISO TS15066, each robot offers four modes of collaborative operation and can easily shift between collaborative speed in PFL mode or full speed in industrial mode, optimizing cycle times based on risk assessment and process requirements.

The HC10DTP has a 10 kg payload capacity, 1,379 mm maximum reach, 1,200 mm effective reach and ±0.05 mm repeatability. The HC20DTP has a 20 kg payload capacity, 1,900 mm maximum reach, 1,700 mm effective reach and ±0.05 mm repeatability. With an appropriate-sized riser, the HC20DTP robot is capable of loading or unloading a 40 x 48” pallet (up to 80-inches tall) without an elevator.

Installation is quick and efficient. A single cable is all that is needed to connect the manipulator to the controller, resulting in easy setup and reduced expenses for maintenance and spare parts inventory.

Both robots are controlled by the high-performance YRC1000 controller that is built to a global standard and does not require a transformer for input voltages ranging from 380VAC to 480VAC. With a highly compact cabinet (598 W x 490 H x 427 D mm), the YRC1000 uses a standard lightweight teach pendant with intuitive programming. The Smart Pendant featuring Smart Frame patented technology is available as an option.

To learn more, click here