Datalogic: P2X Series – Pushing Power to the Edge

April 21, 2021

Recently, Datalogic, a global provider in the automatic data capture and factory automation markets, was pleased to announce the P2X series, the ultimate smart camera with the unparalleled performance and flexibility of the most innovative vision system. Although very technically capable, the P2X is easily setup and operated.

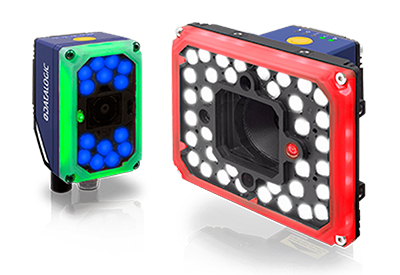

The heavyweight specifications packed into the industrial-grade camera housing will let operators tackle the most demanding of application requirements. The small form factor and large field of view make it the ideal camera on robot guidance applications. The powerful and feature-rich built-in lighting system is designed to be used on production lines for materials of all shapes, sizes and colors. The benefits are endless, and it is undeniable that the new P2X series from Datalogic is a far superior smart camera to all others.

The P2X, with its 2MP resolution and choice of multi-colored illumination, is a versatile solution for manufacturing applications in automotive, electronics, food & beverage, and medical & pharma. It serves as an authority on verifying that components are positioned and assembled correctly before moving into the next phase of the manufacturing process.

Unlike in the past, now operators can easily and effectively move only a single camera through several inspection points, with the help of a robot and the advanced plug and play integration. This new device from Datalogic also comes with full OCR capability, giving customers the added benefit of being able to read labels, and ensure they comply with the entire track-and-trace or serialization needs.

In addition, the P2X is the world’s first smart camera that can detect small displacements from the original set-up. It is equipped with an embedded accelerometer that continuously monitors and tracks the camera orientation. Once the orientation is set up, details are saved to memory and any deviation triggers an instant warning. Operators can stay assured that they won’t have any mistakes usually associated with camera displacements. Any static applications can be repeatedly run without having to worry about positional errors that may occur during repeated operations over time.

The outstanding processing power allows use at the highest production speeds. Combined with a large field of view of the built-in CMOS sensor, the enhanced features of IMPACT™ software, the pattern sort and pattern find, the P2X is more than capable of handling the pace of today’s high-speed manufacturing operations.

The Illuminator LEDs embed TIR lenses to deliver the maximum amount of light onto the field-of-view. Any glare or unwanted reflections are easily removed using optical filters. Coming with a 360° multi-color visual feedback casing, operators and engineers can easily see how the camera is performing without the need to check software or HMI panels.