Comau is Developing Innovative Battery Cell Formation Solutions with the GIGABAT Project in Europe

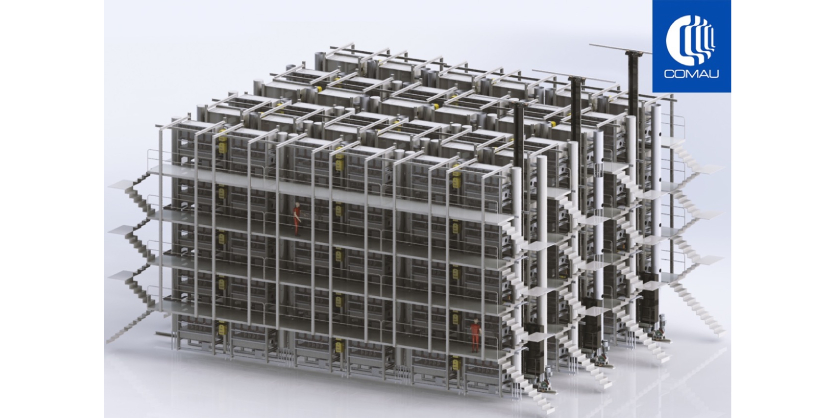

Comau will be developing an energy efficient cell formation chamber as part of its work with GIGABAT, a pan-European initiative aimed a supporting the sustainable and ecological transition towards e-Mobility.

August 8, 2023

- Comau is designing energy-efficient cell formation technologies for GIGABAT, a collaborative e-Mobility project aimed at strengthening the EU production chain for large-scale cell manufacturing

- Targeting an electric and thermal energy savings of up to 20%, Comau’s solution recovers and reuses excess heat and electricity produced during the intense, multi-day cell activation procedure

- The innovative cell chamber design reinforces the automation company’s dedication to industrializing sustainable, cost-effective e-Mobility solutions

- Comau will also leverage proprietary algorithms and digital enablers to further optimize the lengthy and highly complex process

Comau will be developing an energy efficient cell formation chamber as part of its work with GIGABAT, a pan-European initiative aimed at supporting the sustainable and ecological transition towards e-Mobility. As such, GIGABAT seeks to consolidate a large-scale European battery cell manufacturing value chain, with Comau and the other consortium members. Within the scope of the project, Comau’s battery cell formation technology is expected to deliver an electric and thermal energy savings of up to 20% compared to similar solutions available on the market thanks to the recovery and reuse of excess heat and electricity produced during the intense, multi-day cell activation procedure.

Comau’s longstanding commitment to e-Mobility is backed by 50 years of experience in the automotive industry, together with pioneering technologies and expertise in electric vehicle body-in-white, transmissions and e-drive assembly systems, battery manufacturing, and industrialization strategies for next-generation technologies. From a technology standpoint, Comau has a consolidated, field-proven experience for the assembly of electric motors and battery modules and packs (with any cell format – prismatic, pouch, cylindrical) and is also able to cover the last phases of the cell production. By developing new technologies for the manufacturing of cells and advanced solutions for end-of-life battery management, Comau is increasingly able to provide a 360° cradle-to-grave e-Mobility strategy.

Indeed, as part of the GIGABAT project, the Comau’s high-performance cell formation chamber will be designed to optimize the recuperation and reuse of electric energy and heat while delivering a compact chamber layout and warehouse management strategy compared to alternative solutions. To do so, the company will leverage innovative power distribution systems and energy-efficient power electronics (PE) to avoid energy losses while reducing overall energy demand. Comau will also rely on its proprietary algorithms and powerful digital enablers to further optimize the lengthy and highly complex cell formation process.

Led by Cidetec Energy Storage, GIGABAT is bringing together European companies and suppliers that can help Europe achieve a leadership position in battery cell production while optimizing energy efficiency and resource utilization. In parallel, the project aims to promote collaboration between industrial-scale cell manufacturers, battery process equipment companies, material suppliers, and grid energy providers, all of whom will ensure that sustainability and efficiency standards are met every step of the way.

“Europe is moving towards an increasingly self-contained battery production chain and energy-efficient cell manufacturing is key to achieving this goal. e-Mobility already represents a relevant and fast growing part of Comau’s business portfolio. Initiatives such as Gigabat, which go hand-in-hand with our technology development strategy and our ongoing dedication to enabling and optimizing sustainable automation, will allow us to increasingly cover all phases of the electrification life cycle achieving up to 20% electric and thermal energy savings.”

As part of the company’s firm commitment to energy transformation solutions, Comau is actively involved in three of Europe’s top battery consortiums, having joined the European Battery Alliance (EBA), the Batteries European Partnership Association (BEPA) and the European Technology and Innovation Platform (ETIP) at the beginning of 2021. Similarly, Comau is a partner of Upcell – European Battery Manufacturing Alliance, an association that promotes the creation of an integrated European value chain for the development and production of electric batteries, and is also participating in numerous other projects regarding electrification as part of the HORIZON 2020 and HORIZON EUROPE programs.

More Information

Related Story

Flex-BD – Comau is Developing a Fully Automated System for Sustainable Battery Recycling and Second-Life Repurposing

Comau has renewed its commitment to the EU’sFlexible Battery Dismantling (Flex-BD) project for the second year, to help deliver a fundamental pillar on the path towards a truly circular economy.