Flex-BD – Comau is Developing a Fully Automated System for Sustainable Battery Recycling and Second-Life Repurposing

June 7, 2023

Flex-BD – Comau is Developing a Fully Automated System for Sustainable Battery Recycling and Second-Life Repurposing

- Comau continues its participation in the renewed EU project “Flex-BD” for which it is developing a robotized electric battery dismantling cell as part of its on-going commitment to advancing sustainable electric mobility solutions

- With a view to the circular economy, Comau will test and validate the solution as a first step towards cost-effective second life repurposing of automotive batteries

- The Comau-designed cell will facilitate the manipulation of low-charge batteries while minimizing risks to operators and equipment

Comau has renewed its commitment to the EU’sFlexible Battery Dismantling (Flex-BD) project for the second year, to help deliver a fundamental pillar on the path towards a truly circular economy.

Flex-BD is a robotized system that automates the entire process of dismantling worn-out electric batteries using a highly flexible, repeatable and standardizable process. Now, having validated the proof-of-concept, Comau has expanded the scope to include second life repurposing of automotive batteries. In doing so, Comau, in collaboration with other partners within the EU EIT Manufacturing community, is taking an important step towards greater sustainability within eMobility.

Comau estimates, based on the predicted electric battery production volumes within Europe over the next several years, that the EU could easily have over 1 million discarded batteries to be reused by 2030. To this end, Comau is helping anticipate what it believes will be a growing market demand for powerful electric battery recycling and repurposing solutions. In tandem, it will enable businesses to reduce waste and optimize the reuse of raw materials contained within battery packs.

Flex-BD represents a significant improvement to manual handling processes that often include repetitive and heavy tasks in addition to contact with potentially harmful substances. It therefore makes the recovery of battery modules and their components more efficient and sustainable while having a positive impact on workers’ health and safety.

With second-life battery repurposing, on the other hand, the fully automated manipulation of low-charge batteries minimizes risks to both operators and the dismantling equipment. Unlike the materials recovery and recycling process, in which the battery is completely discharged and destroyed, second-life battery repurposing is done while maintaining a low but active battery charge.

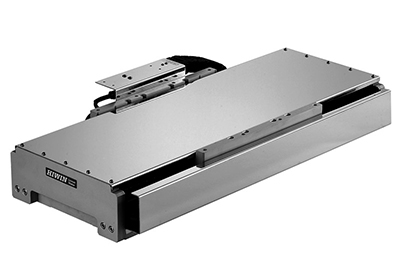

The way the Flex-BD cell works is as intuitive as it is innovative. One by one, battery packs are introduced into the specialized cell where a high-payload Comau NJ industrial robot automatically executes its path and changes its end-effectors based on the required application. In a typical recycling application, for example, the robot unscrews the battery cover, changes grippers to remove the cover, re-attaches the screwdriver to unscrew the modules and then using its gripper moves the pieces to a dedicated storage area.

What’s more, Flex-BD is designed around a highly flexible programming approach based on a reduced use of codes, state-of-the-art environmental perception techniques and the robot’s reactive capacity, the entire dismantling cycle is defined through CAD. The use of LowCode programming also allows operators to quickly and easily redefine the cycle with no need to reprogram the robot.

Comau’s efforts to advance green energy deployment extend beyond its expertise in automated manufacturing systems for batteries, electrical motors and drive units, competencies that are key to enabling the mass production of electric vehicles. At the same time, the company is addressing several key technical and development aspects of the automation process for battery cell manufacturing, including process design and assembly of rechargeable cells, as well as the use of renewable energy and second-life strategies for automotive batteries.

“Our work with the Flex-BD project leverages Comau’s long standing automation expertise in the development of flexible, scalable and sustainable processes,” said Pietro Gorlier, CEO at Comau. “By expanding our smart automation solution to include second life repurposing of high-power batteries, many of which have a residual capacity of up to 80%, Comau is making a concrete contribution to the realization of truly sustainable mobility.”

Pietro Gorlier, CEO at Comau

Related Story

Comau Unveiled as Intrinsic’s First Industrial and Innovation Partner, Demonstrating a True Acceleration in Advanced Automation Solutions

Comau unveiled as Intrinsic’s first industrial and innovation partner. These deep innovation partners have been working together for years, applying the latest in software and AI to the process of robotic programming and robotics-based solution building. The partners have similar aims to democratizing automation by adding intelligence to robots and making programming easier and more widely accessible.