Why IO-Link Is Like an Industrial Version of USB

July 16, 2021

By Colin Cartwright, System Sales Manager, MURR CANADA

Unless you’ve been hiding in a cave for the past few years, you’re probably running into a lot more sensors and I/O components offering IO-Link to communicate with the PLC. With all this IO-Link buzz in the air, I’d like to explore all the exciting possibilities that IO-Link brings to automation and industrial connectivity with you, over the next few months. Let’s start with a quick introduction to IO-Link and its similarities to a connection technology we use every day.

Way back in the early 1990s there was a strong possibility that if you wanted to connect a computer mouse to a PC, you’d need to have a basic understanding of RS232 serial communication to get it to work. Back then, computer mice were still being connecting to a PC with a 9-pin DSUB connector using RS232 for communication. If you didn’t know how to set up your serial ports with the correct speed, parity, and stop bits you could literally be there for hours trying to get your mouse to work.

In those days, serial ports were just one of many different types of connectors you would find on the back of a PC. In addition to that 9-pin DSUB connector, there was another 25-pin DSUB serial connector, an AT keyboard port, an RJ45 Ethernet port, a parallel port, a VGA port, a joystick / MIDI port, sound ports, and possibly a SCSI port or another type of propriety port that enabled you to connect external devices like floppy disk drives, hard drives, and scanners.

Things improved a little when IBM introduced PS2 ports for the keyboard and mouse, but even then, the back of every PC was a real smorgasbord of different connectors and there were no real standards between device manufacturers.

That all started to change when Intel released the first version of the Universal Serial Bus (USB) connector. Yes, we are talking about that same USB connector that you can find on every single computer and many other devices these days. First introduced in 1994, USB was quickly and unanimously adopted by the whole PC industry and ultimately became the standard connector for everything from mice and keyboards to hard drives and printers. The Universal Serial Bus replaced all those clunky legacy connectors on the back of PCs and really standardized the way we connect external devices to our computers. USB truly was a revolutionary technology that changed the whole PC connectivity industry for the better and it still continues to evolve today.

I think IO-Link is the industrial equivalent of USB and will be just as revolutionary. In fact, if you study IO-Link and USB in detail, you will find a lot of similarities:

- – USB and IO-Link were developed to be universal and standardize the communication between controllers and external devices.

- – USB and IO-Link were both designed to provide point-to-point “one device per port” connectivity.

- – USB and IO-Link are based on simple serial communication.

- – USB and IO-Link both provide bi-directional communication to and from a connected device.

- – USB and IO-Link devices are typically connected using quick connectors.

- – USB and IO-Link both require device driver files to be installed to function.

- – USB and IO-Link device parameters can be changed or updated while the system is running.

The only technical differences between the two are the operating voltage and the number of wires – USB operates at 5V using 4 wires (2 for power and 2 for separate transmit and receive). IO-Link operates at 24V using 3 wires (2 for power and 1 for combined transmit/receive).

Also note that although USB devices require a driver file to be installed, they often get installed automatically by the Operating System so you might not be prompted to install one. The driver file for IO-Link devices is called an IODD (IO Device Description) file and you’ll likely need to install it yourself.

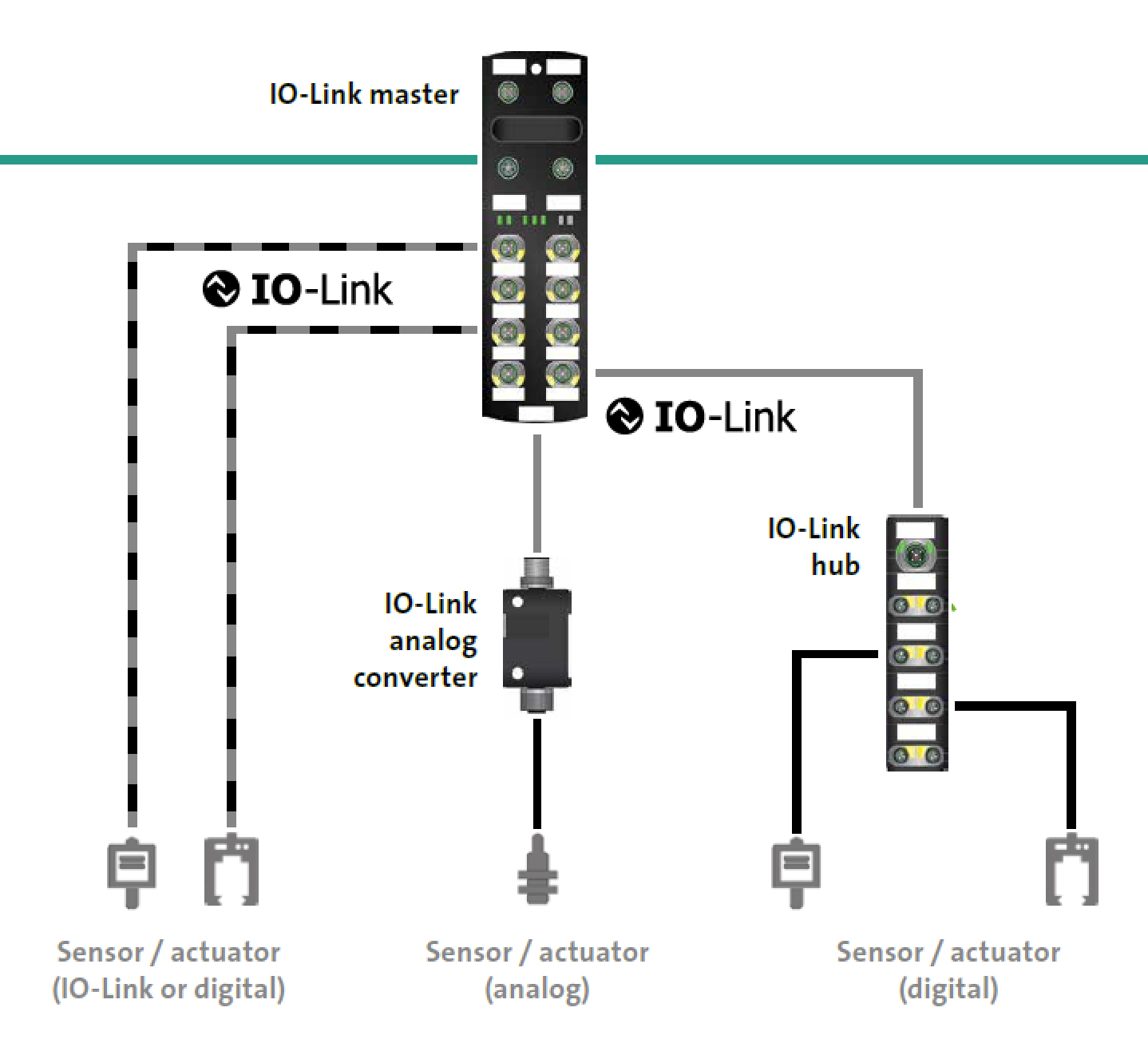

Besides the technical similarities to USB, IO-Link also eliminates several different types of older PLC cards/modules you might still be using in your control system. A single I/O module with IO-Link ports can eliminate many of the traditional PLC cards like analog input or output cards, thermocouple or RTD cards, RFID modules, and many other types of dedicated connection at a fraction of the cost.

IO-Link devices can also save you a substantial amount of time setting up the parameters on your I/O devices. You will no longer have to navigate through a maze of parameters on those LED displays you find on laser sensors or fiber-optic amplifiers to change a parameter. Just connect your laptop to your I/O network and you can change all the parameters on all your devices from the comfort of your desk.

IO-Link will also speed up your I/O system installations and eliminate the time and money needed to run separate shielded cables to your analog devices.

IO-Link (also known as IEC 61131-9) is the first globally recognized standard for communication between industrial controllers and I/O devices. Nearly every I/O device manufacturer is now making IO-Link versions of their devices and with the demand for IO-Link devices continuing to soar, it won’t be long until all those analog devices end up like serial computer mice – obsolete and redundant.

The IO-Link revolution has started and it’s definitely not a fad. IO-Link can bring many benefits to your control system so if you want to stay ahead of your competition and reduce your control system costs, it’s a good idea to get up to speed on IO-Link as fast as possible.

Next month, we will dig deeper into the technical side of IO-Link and explain the difference between Class A and B connections amongst other things. If you’re interested in learning more about IO-Link don’t hesitate to get in touch with me or my Murrelektronik colleagues around the world.

For more information, visit https://www.murr.ca/ca-en/.