How Omron’s Vision-Integrated Cobot System Enhanced Quality Inspection for Their Customer, a Well-Reknowned PCB Manufacturer in the Electronics Industry

November 26, 2020

Most printed circuit boards (PCBs) are produced in large quantities, and there’s plenty of demand for multi-layer, high-density interconnected (HDI) boards; in this process, there’s a considerable amount of manual inspection involved and manufacturers are shifting to automated solutions that can highly improve their inspection process.

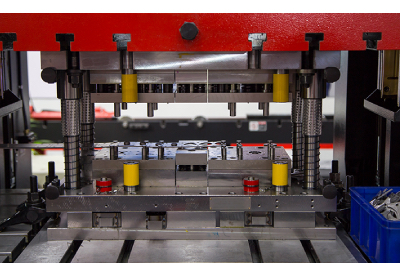

A leading PCB manufacturer asked Omron for help with developing a more efficient and reliable inspection process. Omron combined their FH Series vision system and TM Series collaborative robot to create a fully integrated automated inspection solution that’s accurate, affordable and easy-to-set-up in existing environments.

Understanding Omron’s collaborative robot technology

Omron’s TM Series collaborative robot (cobot) is a versatile solution that can be adapted to numerous applications, including loading and unloading, pick and place, assembling, testing, mounting, soldering, to name a few. The cobot’s simplified programming requires no coding, so startup is quick and easy.

A built-in, intelligent vision system enables pattern recognition, object positioning and barcode identification. Ultimately, the TM Series represents a major step forward in creating an intelligent and flexible manufacturing environment where humans and machines can work in harmony.

The power of a turnkey solution

After considering several strategies, Omron’s customer decided to build the solution around the TM Series cobot and other proven Omron technologies like the FH Series vision system, the NX Series controller and Sysmac Studio. The PCB manufacturer wanted a turnkey system that could be easily supported by its field service providers.

The cobot enabled the team to place the inspection station alongside workers without having to include an expensive safety cell. The fully integrated solution incorporates traceability infrastructure, integrates easily with third-party systems, and reduces the effort required to program the robot to inspect new PCBs.