How Edge-Based and Cloud-Based Solutions Complement One Another by Omron

March 17, 2022

For manufacturers looking to get started with the Industrial Internet of Things (IIoT), a common question that comes up is whether they should use the edge or the cloud for data analysis purposes. However, this does not have to be an either-or choice. In fact, both strategies are optimized to fit different needs and can work well together.

Some manufacturers do not want their data going into the cloud for proprietary reasons. In these cases, a total edge solution is preferred. But customers willing to let some of their data leave, an edge-cloud combo could work wonders. Omron looks at why this is.

Some decisions need to be made extremely quickly

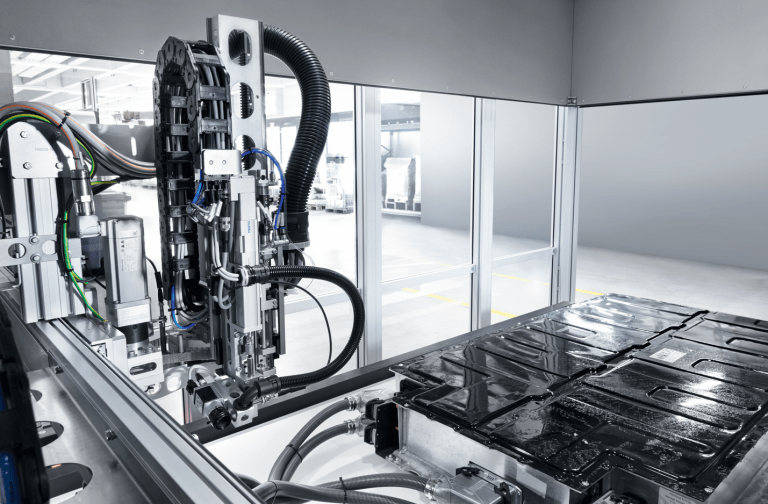

One thing that’s great about the edge is that it lets you react in real time. You can analyze data and make changes immediately. Our artificial intelligence (AI) controller, for example, uses machine learning algorithms to detect anomalies in machine behavior, alert operators that something’s amiss, and automatically go into a preprogrammed alternate run mode.

An edge-based strategy brings manufacturers closer to the vision of the factory of the future, in which equipment on the factory floor uses real-time data analysis to autonomously make adjustments. Since there’s no need to send data to the cloud for analysis and then communicate it back to the facility, decisions can be made extremely quickly.

Some decisions must be based on long-term data analytics

The one caveat with respect to edge-based data analysis and decision-making is that you’re only looking at a small slice of data. This is great for decisions that are just based on what’s happening now, but it won’t help you analyze trends that occur over long periods of time (like seasonal variations).

A cloud-based strategy lets you analyze data on a broader scale to detect how – for example – seasonal weather conditions might affect a process. If it’s warmer inside the plant, materials may react differently than they would when it’s cooler. You can also identify patterns of equipment wear and tear and detect operator training needs with longer-term analysis.

If you want a true edge solution, Omron is the best choice

Omron is special when it comes to helping customers stay completely on the AvevaEdge. Other automation solution providers also offer edge enabled devices, but these typically they require some sort of connectivity for licensing or updates. Only Omron can truly stay on the edge, and our AI controller is one of the most secure ways for manufacturers to leverage machine learning.

Want to learn more about Omron’s smart manufacturing solutions?

Check out their IIoT solutions portfolio here