80% More Productivity in Additive 3D Printing

DMG MORI Additive strengthens SLM process with automation technology

February 1, 2024

“Our aim is to achieve a high level of maturity of CNC machines with our additive manufacturing machines,” explains Dr. Vino Suntharakumaran, Managing Director at DMG MORI Additive GmbH. The company is not far off reaching this aim with the LASERTEC 30 DUAL SLM, which increases productivity by 80%. Festo has been brought on board as a development partner. Thanks to its ready-to-install automation solution, the inert gas atmosphere is precisely managed.

The LASERTEC 30 DUAL SLM from DMG MORI Additive is the flagship for additive manufacturing by selective laser melting (SLM) in a powder bed. It produces highly complex components with function integration, internal close-contoured cooling channels and reduces product development times thanks to prototypes made of series materials that are available straightaway. Two powerful 600 W lasers, each with scan fields covering the entire installation space, enable build rates of up to 90 cm³/h.

Faster and safer powder module change

Other advantages: the dual-laser system improves productivity by 80% compared to a single-laser system. The powder module for quick material change, called rePLUG, automates powder handling. Reprocessing the powder in an inert gas atmosphere ensures greater efficiency and occupational safety thanks to the closed material circuit. With the powder module, it is possible to switch between different materials in less than two hours and without any contamination.

Another innovation is the permanent filter system, which works independently of the material and offers a new level of durability and occupational safety thanks to the automatic passivation of metal dusts. Since the installation space is actively cooled, users can remove finished components earlier and thus prepare new jobs more quickly. The result is a further increase in productivity.

Process gas fully under control

The process gas atmosphere plays a decisive role. It is important that the pressure and oxygen content remains within narrow limits to ensure high component quality. “A Festo automation solution helped us achieve a breakthrough here,” says Suntharakumaran. The solution consists of a unit for filling the working chamber with inert gas. Only a safe inert gas atmosphere ensures stable processes in additive manufacturing. “The prerequisite for this is innovative products for flow and pressure control, which we get from Festo,” adds 3D expert Suntharakumaran.

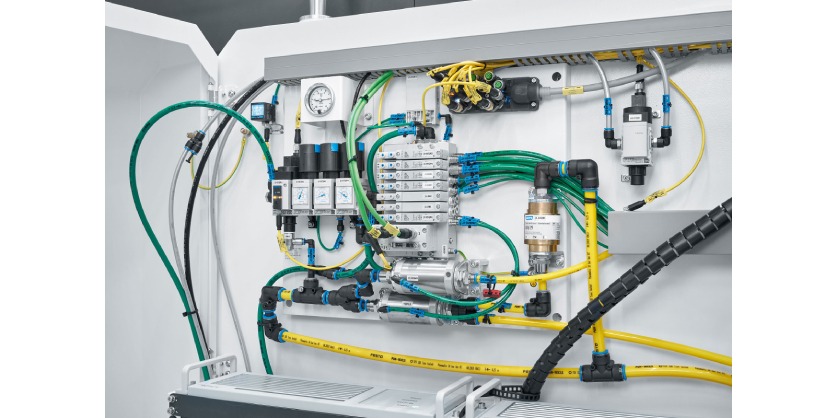

The ready-to-install complete solution from Festo consists of a mounting plate equipped with the valve terminal VTUG including EtherCAT bus connection, the pinch valve VZQA, the MS4 service unit and the proportional-pressure regulator VEAB. The valve terminal VTUG is suitable both in terms of pneumatics and control technology. The pinch valve VZQA precisely controls the inert gas argon and the evacuation of the gas mixture during the purging process.

Innovative automation solution

The proportional-pressure regulator VEAB is compact yet has precise and dynamic control characteristics. These valves offer high-precision flow control at up to 20 l/min. with low hysteresis, high repeat accuracy and low energy consumption. The proportional characteristics of a piezo bender with direct actuation ensure stable and reliable regulation and a stepless pressure rise. The MS4 service unit has a modular design for compressed air supply and its components can be freely combined. These include pressure regulators, on/off and soft-start valves with safety function, filters, pressure and flow sensors, dryers, sensors and lubricators. This means there is a solution for every task.

All automation products used are suitable for inert gases. “This solution keeps the pressure and oxygen content within narrow limits,” adds the 3D printing expert. It also halves the cycle time by shortening the time needed to fill the workspace.

Simulation software also in demand

Festo services are not limited to supplying the automation solution. The automation manufacturer’s experts were also involved in developing the machine. With appropriate software and engineering tools from Festo for simulation, it was possible to embed the automation components in the machine and the development processes at an early stage and thus become part of the solution early on.

DMG MORI, as one of the world’s leading companies in machine tool manufacturing, is further expanding its technological leadership. “That is why it is important for us to join forces with innovative partners. Festo is such a partner for us, because as a manufacturer of pneumatic and electric automation technology it focuses and works on future topics, as can be seen in bionic grippers or the Festo AX digitalisation solution,” explains Suntharakumaran. They are thus both looking for further solutions to automate labour-intensive activities, for example when loading and unloading the construction cylinder.

About DMG MORI:

DMG MORI AKTIENGESELLSCHAFT is a leading global manufacturer of machine tools with a turnover of over € 2.0 billion and more than 6,800 employees. Around 12,000 employees of this “Global One Company” are in direct contact with over 100,000 customers from 55 industries. DMG MORI is present in 87 countries worldwide – with 16 production plants and 111 sales and service locations. The company is actively driving the future topics of automation, digitalisation and sustainability.

High-precision machine tools and sustainable technologies from DMG MORI are used at the start of global value chains. Comprehensive automation and end-to-end digitalisation solutions expand the core business with turning and milling machines, advanced technologies and additive manufacturing.

About Festo

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries.

Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,800 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.81 billion in 2022. Each year around 7% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.

Related Product

Moving Into the Future with Controlled Pneumatics from Festo

In Controlled Pneumatics, Festo combines proportional technology, sensors, and control algorithms to form a control loop. These are mechatronic pneumatic systems with innovative valve and communication technology that enable digital influence in conjunction with closed-loop control based on a sensor variable. This technology creates new areas of application, especially for pressure and flow control, that push the limits of pneumatics and enable simpler, more reliable, faster, more precise, and more efficient solutions. Conventional standard pneumatics, on the other hand, are used specifically for simple applications such as point-to-point movements. It is above all the simplicity of standard pneumatics that makes it the ideal solution in many cases.