Güdel Introduces Swiss Quality Tracks for Cobots

May 9, 2025

CoboMover™ is a robust linear track for cobots and small industrial robots launching at Automate 2025. At the show, Güdel is also showcasing a stunning demo on how air bearings can eliminate the need for cranes or embedded rails, moving 3,800+ lbs on a cushion of air.

From moving cobots to novel mobility solutions, Güdel Inc. is highlighting two new technologies at Automate 2025 booth #2418 that demonstrate its unmatched ability to solve automation engineering challenges.

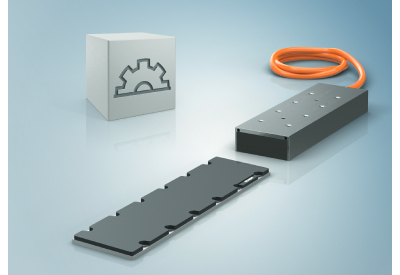

First, Güdel will unveil the Cobomover™, a 7th-axis linear track purpose-built for collaborative and lightweight robots. Designed and manufactured in Switzerland, the Cobomover extends the working range of robots up to 5 meters (16.4ft), allowing them to operate multiple workstations and perform a variety of tasks without manual repositioning. “The Cobomover is more than just another linear axis—it’s a game changer,” says Brenda Courim, Head of Sales for Güdel Inc. “It’s designed to help integrators and end users get the most out of their cobot and lightweight robot investments, with the same quality, repeatability, and ease of use to which Güdel’s customers have become accustomed.”

The CoboMover is compatible with over 60 cobots and small traditional robots. It offers mounting positions at 0° and 180°. The maximum payload, including robot weight, is 78 kg (172 lbs). Its drive system utilizes a toothed belt and Güdel’s HPG045 angular gearbox. Available stroke lengths include 1000, 2000, 3000, 4000, and 5000 mm. The CoboMover has a maximum speed of 2 m/s and a maximum acceleration of 2 m/s², providing a repeatability of ± 0.05 mm.

Gliding on a cushion of air

With its reputation for robust track systems, heavy-payload gantries, and high-precision motion components, the company continues to expand its footprint by helping automation integrators solve real-world challenges. A recent example of this to be showcased at Automate, is a modular track system fitted with air bearings. Using just 5 psi, the air bearing solution is able to levitate the TMF-4B track – weighing 3,800 lbs – half an inch above ground, enabling it to easily float into and out of position on a cushion of air. The solution was initially developed for aircraft painting applications, eliminating the need for cranes, high-payload forklifts or embedded rails.

The innovation solves two major constraints: mobility within large workspaces and facility layout limitations. “This was an application-specific solution,” says Mike Peek, Marketing Manager at Güdel Inc., explaining how an integrator came to Güdel with a challenge: move a precision paint robot in and out of place without installing embedded tracks in the floor. “Our engineering team delivered a new product that allows the entire track to be moved into and out of the work cell when needed. We look forward to showing these innovations to the Automate audience and discuss how our engineering team can help attendees with their next automation breakthrough,” says Peek.

About Güdel: Güdel Inc. is the US subsidiary of Güdel Group, a global manufacturer of robotic automation products, systems, and services. The company supplies linear motion modules, robot track motion units, gantry robots, and components to the automotive, aerospace, logistics, heavy industrial, press automation, and power generation industries. Güdel US is headquartered in Ann Arbor, Michigan in a dedicated 45,000-square-foot facility, providing North American customers with engineering, design, production, and customer service support.