How to Create 75% Higher Throughput Palletizing with the Multipick by Robotiq

February 15, 2023

Collaborative robot palletizing can be the perfect tool for improving the productivity of your end-of-line process. Compared to manual palletizing, it is more efficient, consistent, and scalable.

There is one thing that can still hold you back from getting the productivity you need: number of picks per minute.

For the vast majority of situations, the speed of an out-of-the-box robotic palletizing solution is more than sufficient. However, sometimes, you might need a higher throughput than the base solution can provide.

For this reason, we recently released the multipick feature. This software enhancement allows a robot to pick and place multiple cases simultaneously. Multipick can drastically increase the throughput of your palletizing robot, helping you keep up with faster production lines.

Our customers are already seeing impressive results. One company in the pet food industry achieved an astounding 75% higher throughput using the multipick feature.

Here’s how you can use multipick to improve your palletizing throughput.

What is the Multipick Feature?

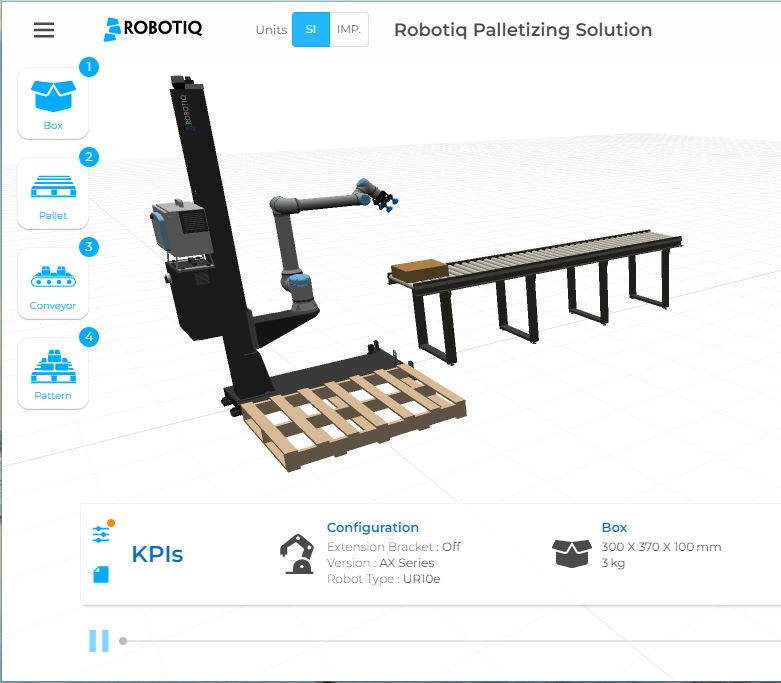

The multipick feature is a software enhancement to our Robotiq Palletizing Solution. It enables collaborative robots to complete palletizing cycles faster by allowing them to pick up multiple cases simultaneously.

For example, before you could only solve uneven pallet patterns in Single Pick mode, which impacts pallet completion times. Multipick now allows you to leverage Always Dual Pick mode to increase throughput capacity, and still set the cobot to Single Pick in pallet pattern situations where two boxes cannot be placed consistently and simultaneously.

All robotic palletizing helps reduce manual palletizing, but multipick means more of those unusual “edge cases” can now be handled by a robot along with more standard palletizing tasks.

6 Compelling Reasons to use Multipick

What are some of the benefits of using multipick?

- Increased Throughput — By picking and placing multiple cases simultaneously, you can drastically increase throughput.

- Reduced Movement Time — Excessive robot movement is one of the leading wastes of robotic setups. Multipick helps reduce this to a minimum.

- More Flexible Picking — The extra control provided by multipick makes robotic palletizing more flexible.

- Easy Setup and Configuration — The multipick feature is easy to configure within the programming interface of the Robotiq Palletizing Solution.

- More Application Fit — Meet today’s throughput requirements, and prepare for the ability to meet future demand.

- Faster Return on Investment — By increasing your palletizing throughput, your robot will achieve a faster return on investment than without multipick.

Multipick is an excellent addition to the Robotiq Palletizing Solution, helping you to elevate your robotic palletizing setup even further.

How One Company Achieved 75% Higher Throughput Using the Multipick Feature

Throughput is a key factor in the pet food industry, where the size and efficiency of batch production can directly affect a company’s ability to stay competitive. In order to keep up with increasing demand and ambitious production goals, companies must ensure that they are doing all they can to optimize their end-of-line packaging processes.

One robot user in the pet food industry had a goal of palletizing 10 to 13 boxes per minute in their end-of-line process. With a regular robotic palletizing setup, this was not looking possible once they factored in the added slip sheets between pallet layers and pallet changes.

We suggested they add multipick to their palletizing setup. The feature would allow them to pick multiple boxes simultaneously, shaving significant seconds off their cycle times

With multipick, they achieved their target and significantly surpassed it. The final cycle time was an impressive 17 to 22 boxes per minute, including interlayer placement and pallet changes. This was 30-120% better than their target, which we can approximate to a conservative 75%.

The multipick feature made a huge difference to the user’s palletizing process. It allowed them to meet their production needs and left extra room for even further capacity in the future.

What Palletizing Throughput Could You Achieve?

The 75% improvement in the example is impressive, but the most important question is how multipick could benefit your business.

The software feature greatly increases palletizing throughput and reduces the time spent on each palletizing cycle. It can help you save money, improve customer satisfaction by ensuring products are available when needed, and allow your business to better compete both price- and volume-wise while minimizing operating costs.

How much could you boost your palletizing throughput by leveraging multipick? Try the configurator and find out!

Related Story

Robotiq’s 2 New Product Offerings for Easier Palletization: The PowerPick and Multipick

The PowerPick gripper and the multipick software from Robotiq are both designed to extend the range of palletizing applications, both in payload and throughput.

PowerPick is a vacuum gripper specifically designed for palletizing purposes. It offers flexibility to help manage a wide range of box sizes, shapes, weights, and packaging materials. It’s also reliable when exposed to less controlled conditions, such as humidity and fine dust