Mecademic Reaches New Milestone: 15% of Robots Shipped Now Power Optics and Photonics Applications

April 23, 2025

Mecademic, a pioneer in ultra-compact, high-precision robotic solutions, has announced a major milestone: 15% of all robots shipped in the past 12 months have been deployed in optics and photonics applications. This achievement reflects the company’s growing influence in high-tech manufacturing and underscores the rising demand for scalable microautomation in precision-driven industries.

“This milestone reflects the increasing adoption of our microautomation solutions in the optics and photonics sector,” said Philippe Beaulieu, CCO and Executive Vice President of Mecademic. “We’re not just delivering robots — we’re enabling the next generation of compact, precise, and cost-effective manufacturing.”

Key Highlights:

- Micron-level precision and resolution: essential for optical alignment, gluing, and component placement

- Cost-effective automation: replacing manual tasks and bulky traditional optical positioners

- The Meca500: the world’s most compact six-axis industrial robot, easily integrates into space-limited environments

Mecademic’s robotic solutions are transforming production processes across a wide spectrum of emerging technologies, including:

- Virtual Reality (VR) headsets

- Augmented Reality (AR) smart glasses

- High-precision lasers

- LiDAR systems for autonomous vehicles

- Advanced optical sensors and photonic components

Among Mecademic’s innovations is the Meca500-OB, a variant featuring an optical black surface treatment that absorbs 96.5% of visible light — a key advantage for sensitive optical applications where even minor light interference could compromise accuracy or safety.

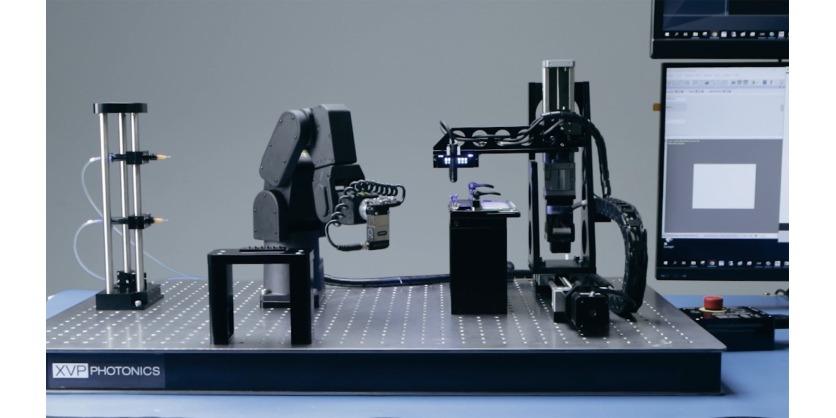

To showcase how its robots are redefining precision workflows, Mecademic partnered with XVP Photonics to create a real-world demonstration highlighting automated micro-optics alignment. This demo, detailed in the white paper “Automating Micro-Optics Alignment with the Meca500,” will be presented live at Laser World of Photonics 2025, June 24–27 in Munich. Attendees will experience firsthand how the Meca500 delivers unparalleled precision and adaptability in photonics manufacturing.

Its strengthened regional presence further supports the company’s expansion across Europe. Stefan John, recently appointed Sales Area Manager for Germany, Austria, and Switzerland (DACH), will represent Mecademic at Hannover Messe 2025, taking place March 31 – April 4 in Hanover.

“Our presence in Germany allows us to support Europe’s growing demand for microautomation, particularly in the thriving optics and photonics space,” said Stefan John. “We’re excited to connect with partners and showcase the transformative impact of compact robotics firsthand.”

From Hanover to Munich, Mecademic’s European 2025 showcase brings the forefront of robotic precision and innovation to key industry stages.

About Mecademic

Based in Montreal, Canada, Mecademic designs and manufactures the world’s smallest and most precise industrial robots. Focused on innovation, simplicity, and performance, the company is redefining factory automation across key sectors, from optics and photonics to medical devices and advanced research.

More Information

For more information or to access the white paper, visit www.mecademic.com or follow them on LinkedIn.

Related Story

SDC Automates a Complex Assembly Process with Mecademic’s 6-Axis Robot

Learn how Steven Douglas Corp. (SDC), an industrial automated machine builder, integrated the Meca500 to automate a complex medical device assembly process for one of its customers at a microscopic level.