Festo Introduces the VTUX, the Company’s New Flagship Valve Terminal

December 3, 2024

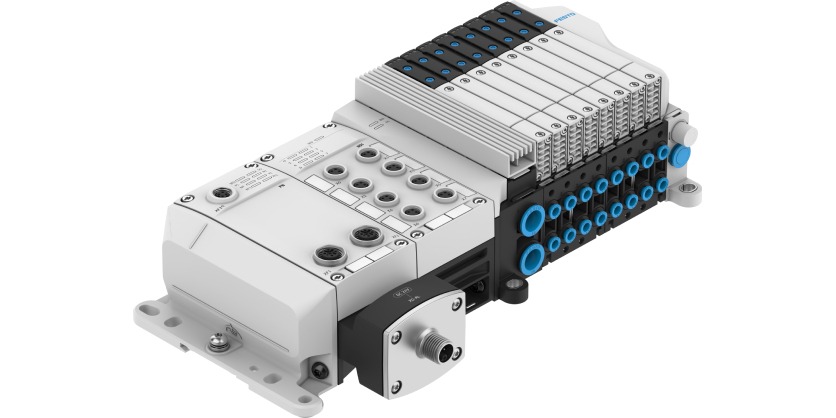

Festo introduces its new flagship valve terminal, the VTUX. The VTUX can serve as I/O, remote I/O, and decentralized I/O. These compact and rugged IP65/67-rated terminals can be located anywhere on a machine that boosts operational performance and original equipment manufacturer (OEM) installation productivity. VTUX modularity results in less inventory and lower overhead costs. Slated to replace Festo’s legacy terminals, the VTUX will be the company’s star for years.

VTUX is both compact and lightweight, an advantage for end-of-arm tooling and conserving space on a machine or in a control cabinet. The terminal is made from a high-performance polymer so rugged and durable that these units can be placed in welding cells.

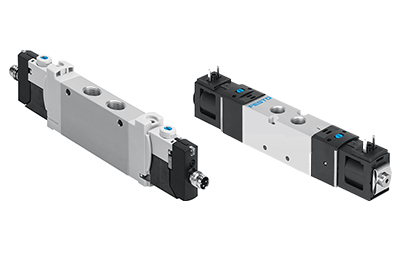

The key to the VTUX’s unparalleled flexibility is its modular design. For high flow rates up to 670 l/min, a high flow subbase is used and for space saving needs, the compact subbase. A single valve model can be used for both subbases, which simplifies ordering, stocking, and support. High flow and compact subbasses of one or four valve positions can be mixed and matched on a terminal. VTUX terminals can have up to 128 valves with up to 128 solenoid coils. The VTUX also features vacuum capability.

The electronics side of the terminal offers the same flexibility as the pneumatics side by featuring mix and match modules. For example, users can add multiple analog or digital I/O modules, including I/O-Link. The modular concept continues through to the method of communication between controller and terminal. The choices include the new Festo Automation Platform (AP) for backplane speed communication in all top communication protocols. All AP-based modules appear to the control engineer to be under a single IP address, which simplifies commissioning and allows smaller and less expensive PLCs to be specified. Additional communication modules include IO-Link, AP-I for decentralized I/O, and multipin connector.

VTUX terminals are assembled and tested prior to shipment from the Festo Regional Service Center in Mason, Ohio, which means they are drop-in ready for installation. As a core Festo product, VTUX components are stocked globally for fast, assured replacement and minimum downtime wherever the machine is located. The modular design not only lowers inventory but also lowers the learning curve, troubleshooting time, and repair. The VTUX offers an outstanding price/performance ratio.

More Information

For more information on the VTUX modular valve terminal, visit the Festo website and contact a Festo sales representative or distributor. For more information on the advantages of working within the Festo ecosystem of less engineering overhead, fast time to market, seamless connectivity, and high-quality components, visit www.festo.com.