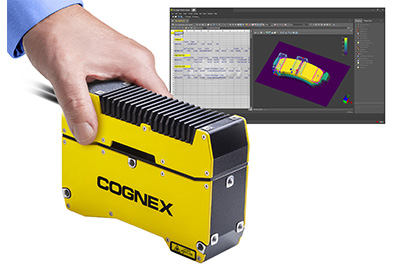

Cognex Introduces the In-Sight 3D-L4000 Vision System

January 13, 2020

Cognex Corporation has recently introduced the In-Sight 3D-L4000 embedded vision system. Featuring 3D laser displacement technology, this first-of-its-kind smart camera allows engineers to quickly, accurately, and cost effectively solve a range of inspections on automated production lines.

“Until now, 3D has been too expensive and complicated to solve inspection applications for most customers,” John Keating, 3D Business Unit Manager. “The In-Sight 3D-L4000 breaks previous barriers by providing a massive suite of true 3D vision tools and making them as easy to use as the industry leading In-Sight 2D vision tools.”

The 3D-L4000 combines patented speckle-free blue laser optics and the broadest range of true 3D vision tools with the flexibility of the In-Sight spreadsheet. This all-in-one solution quickly captures and processes 3D images with spectacular quality during inline inspection, guidance, and gauging applications.

By allowing users to place vision tools directly on a true 3D image of the part, the 3D-L4000 delivers greater accuracy compared to traditional systems, expanding the types of inspections that can be performed. Moreover, because inspections are in 3D, users can immediately experience how the vision tools operate on the actual part.

The 3D-L4000 includes all the traditional 3D measurement tools users expect such as plane and height finding. It also comes with a comprehensive set of 3D vision tools, designed from the ground up to leverage inspections in a true 3D space.

The intuitive In-Sight spreadsheet interface quickly and easily sets up and runs 3D applications without the need for programming or external processing. It simplifies application development and streamlines factory integration with a full I/O and communications function set. It also enables the ability to combine 2D and 3D vision tools in the same application, leading to faster deployments.

The In-Sight 3D-L4000 comes in three factory calibrated fields of view and is ideal for applications across a range of industries including food and beverage, consumer products, packaging, automotive, medical devices, and electronics.