Guide to Mechatronics – Part 9: Sustainability in Mechatronics

March 20, 2025

As global awareness of environmental issues grows, sustainability has become a crucial consideration in all fields of engineering, including mechatronics. Integrating mechatronic systems in sustainable engineering solutions plays a pivotal role in reducing environmental impact, enhancing energy efficiency, and promoting the sustainable use of resources.

Energy Efficiency:

One of the primary contributions of mechatronics to sustainability is in the development of energy-efficient systems.

- Smart Energy Systems: Mechatronic systems are integral to the optimization of energy consumption in industrial processes, buildings, and transportation, leading to significant reductions in carbon emissions.

- Renewable Energy Systems: Advanced control systems in wind turbines and solar panels maximize energy capture and efficiency, contributing to the growth of sustainable energy sources.

Resource Optimization:

Mechatronics enables the precise control and efficient use of materials and resources.

- Precision Agriculture: Utilizing sensors and automated systems for irrigation and fertilization, which reduces waste and improves crop yield with minimal environmental impact.

- Manufacturing Processes: Automated and optimized manufacturing processes minimize material waste and reduce the carbon footprint of production.

Waste Management and Recycling:

Mechatronic systems contribute to efficient waste management and recycling processes.

- Automated Sorting Systems: Advanced sorting technologies in recycling facilities can separate materials more accurately and efficiently, increasing the recycling rate and reducing landfill waste.

- Waste-to-Energy Systems: Mechatronic systems in waste-to-energy plants ensure optimal operation and energy recovery, providing a sustainable way to manage waste.

Sustainable Transportation:

Mechatronics is at the forefront of developing sustainable transportation solutions.

- Electric and Hybrid Vehicles: Control systems in electric and hybrid vehicles optimize energy use, reducing reliance on fossil fuels.

- Public Transportation Systems: Automated and optimized public transit systems, including electric buses and trains, contribute to reduced urban congestion and pollution.

Incorporating sustainability into mechatronics involves designing energy-efficient and resource-conscious systems and ensuring that the life cycle of these systems, from manufacturing to disposal, minimizes environmental impact.

This requires a holistic approach, considering the source of materials, manufacturing processes, operational efficiency, and end-of-life recycling or disposal.

This article is original content created and posted by Electromate. Please do not re-post this content without prior approval from Electromate.

Related Stories – A Guide to Mechatronics

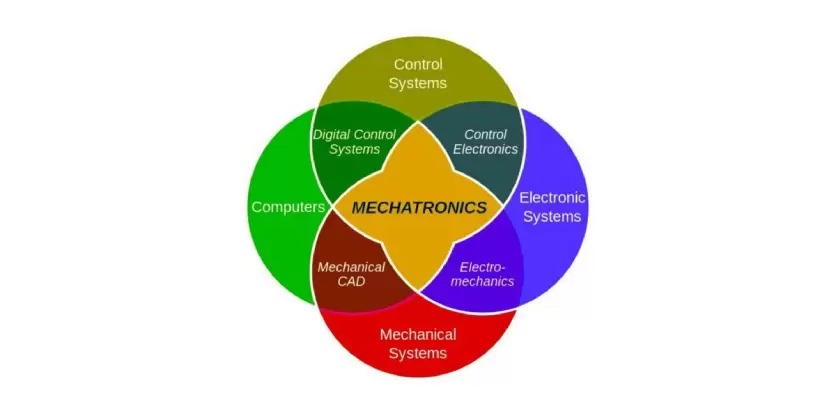

Part 1: Introduction & Fundamentals

Part 2: Composition of a Mechatronic Subsystem

Part 3: Strategies for Integrating Mechatronic Subsystems

Part 4: Software & Programming

Part 5: Tools & Languages in Mechatronics Software Development

Part 6: Applications of Mechatronic Subsystems