Making Industrial Robots More Nimble With NVIDIA Isaac Manipulator and Vention MachineMotion AI

July 9, 2025

By Raffaello Bonghi and Yichao Pan

As industrial automation accelerates, factories are increasingly relying on advanced robotics to boost productivity and operational resilience. The successful deployment of robots depends on capabilities like precise motion planning, accurate spatial perception, and robust obstacle avoidance. AI-enabled robotics and software-defined automation help make factories more autonomous, scalable, and resilient. High-performance robotics software is essential for modern manufacturing.

This blog examines how cuMotion, nvblox, FoundationPose, and FoundationStereo software libraries and AI models in NVIDIA Isaac Manipulator significantly optimize the functionality of AI-enabled robot arms—also called manipulators. These advanced GPU-accelerated tools provide real-time motion planning, precise environmental mapping, and accurate stereo perception, enabling manufacturers to rapidly deploy sophisticated automation solutions with minimal integration complexity.

Optimizing robotic manipulators with NVIDIA Isaac Manipulator

NVIDIA Isaac Manipulator is a comprehensive software solution that simplifies the deployment of advanced robotic manipulator functionalities by harnessing NVIDIA’s cutting-edge, GPU-accelerated software tools. It offers a streamlined approach for implementing complex robotic capabilities into industrial workflows using the following tools:

- cuMotion: GPU-accelerated motion planning

cuMotion provides powerful, GPU-driven motion planning, trajectory generation, and inverse kinematics. cuMotion significantly accelerates real-time robotic-arm operations, delivering rapid and collision-free trajectory execution in cluttered environments. This capability ensures enhanced performance and reliability, critical for industrial robotics applications where precision and efficiency are essential. - nvblox: dynamic real-time 3D mapping

nvblox equips robotic manipulators with real-time 3D mapping capabilities, enabling dynamic spatial awareness and precise environmental understanding. This allows robots to perceive and navigate complex, changing environments accurately; improve obstacle avoidance; and ensure safe operational workflows. - FoundationPose: robust, scalable 6D pose estimation

FoundationPose delivers advanced 6D pose estimation capabilities using RGB-D inputs, with exceptional robustness to lighting conditions, reflections, and varied object geometries. One of the biggest challenges in training physical AI models is the lack of real-world data, unlike language models that can be trained on abundant internet text. To overcome this, their team generated over 5 million synthetic images using Isaac Sim on a computer, then trained FoundationPose using a V100 GPU on a second computer in just a few days. The result is a zero-shot model that requires no training or fine-tuning, generalizes to novel objects, and works out of the box. - FoundationStereo: accurate stereo perception

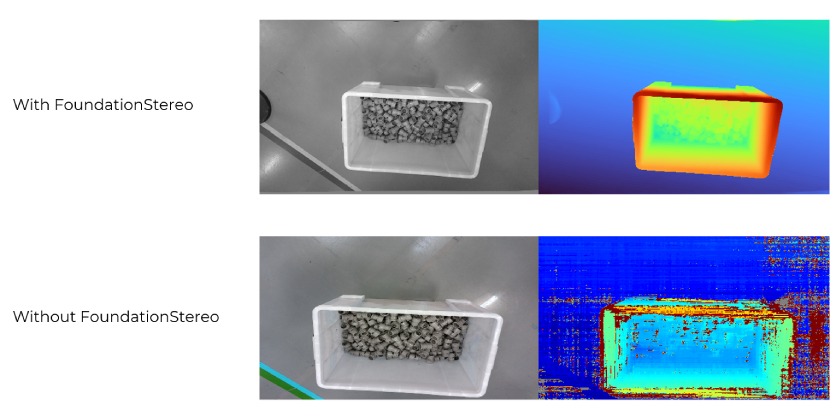

FoundationStereo offers robust stereo vision capabilities that are crucial for high-accuracy depth estimation. Precise perception facilitates reliable interaction with the surrounding environment, enabling manipulators to execute tasks accurately even in complex, cluttered, or dynamic industrial settings. Trained on a massive synthetic dataset, FoundationStereo significantly improves depth quality, even with affordable sensors like Intel RealSense. Its performance earned a Best Paper Nomination at CVPR 2025, distinguishing it as one of only 14 recognized papers from over 10,000 submissions.

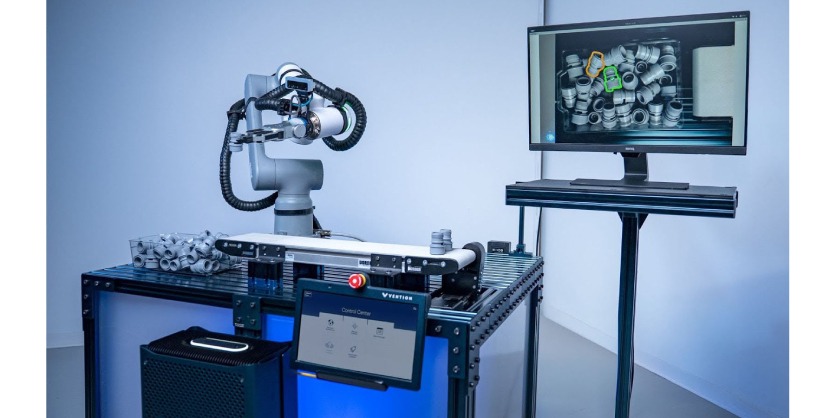

Vention MachineMotion AI

Vention’s MachineMotion AI is an advanced automation controller designed to seamlessly integrate AI-driven robotics directly into industrial workflows. Powered by NVIDIA Jetson Orin and built-in cellular connectivity, MachineMotion AI enables rapid deployment, efficient edge computing, and remote operation of robotic cells, minimizing infrastructure requirements and complexity.

Key applications of MachineMotion AI include:

- Edge-based robotic pick-and-place

MachineMotion AI leverages powerful onboard edge processing from NVIDIA Jetson Orin modules, enabling real-time object detection and localization directly within the robotic cell. This significantly reduces latency and eliminates dependence on external processing resources. - Remote diagnostics and monitoring

Utilizing built-in cellular connectivity, MachineMotion AI empowers engineers to monitor robotic performance remotely, perform diagnostics, and update software components without onsite intervention. - Flexible assembly lines

MachineMotion AI allows manufacturers to swiftly reconfigure robotic cells for diverse tasks because of the AI’s intuitive, low-code software interface and GPU-accelerated motion-planning capabilities that are provided by NVIDIA Isaac Manipulator running on NVIDIA Jetson Orin platforms. This flexibility ensures production lines can adapt quickly to changing product specifications and market demands.

By utilizing NVIDIA Jetson Orin, MachineMotion AI simplifies and accelerates the deployment of scalable, reliable AI-driven robotic systems. It significantly enhances NVIDIA Isaac’s software capabilities and supports agile industrial automation strategies.

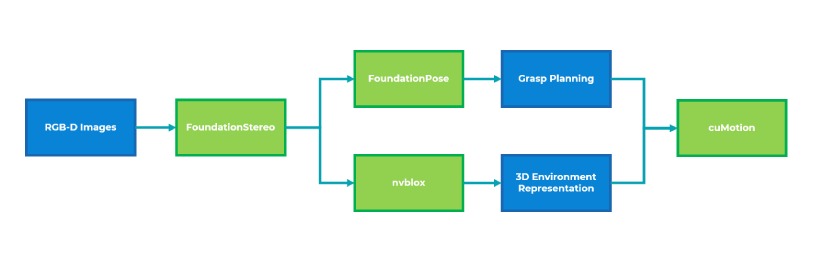

System architecture

The system architecture for robotic deployment integrates NVIDIA Isaac Manipulator with Vention’s MachineMotion AI hardware in an industrial robotic pick-and-place scenario. This architecture consists of three core layers that collaboratively deliver high-performance, real-time automation:

- Perception layer

A depth-sensing camera captures RGB-D input for object detection and pose estimation. NVIDIA FoundationPose accelerates these perception tasks and executes them directly on NVIDIA Jetson Orin hardware, delivering responsive and accurate environmental awareness. When using low-cost sensors like Intel RealSense, FoundationStereo can dramatically improve depth quality based on stereo images. - Planning and control layer

cuMotion utilizes pose data to compute collision-free motion trajectories and solve inverse kinematics for the robotic arm. The GPU-accelerated architecture ensures low-latency, smooth, and precise motion planning for dynamic industrial environments. - Actuation and edge control layer

Vention’s MachineMotion AI serves as the edge controller, generating motion trajectories using cuMotion. It interfaces with robots, actuators, sensors, and network communication layers, managing real-time robotic operations at the production cell level with built-in support for remote diagnostics and updates.

This modular architecture enables flexible and scalable industrial automation, leveraging GPU acceleration and edge control to deliver robust performance in demanding production settings.

Random bin picking system

A representative use case of this integrated system is an industrial random bin picking application, showcasing the combined strengths of NVIDIA Isaac Manipulator and Vention’s MachineMotion AI controller:

- Object pose estimation

FoundationPose processes RGB-D data to estimate object positions and orientations for accurate robotic manipulation. - Trajectory planning and execution

cuMotion receives object position data and rapidly computes optimized, collision-free trajectories. Vention’s MachineMotion AI controller streams these trajectories to the robot controller for execution, enabling precise and reliable robotic arm movement to grasp and relocate items.

This integrated approach delivers real-time perception and motion-planning performance and is well-suited for the complexity and variability inherent in random bin picking tasks within industrial automation settings.

Next steps

Integrating the NVIDIA Isaac Manipulator with Vention’s MachineMotion AI offers a powerful and practical framework for deploying AI-driven robotics in industrial settings. This combined solution leverages GPU-accelerated perception and real-time motion planning at the edge. It enables flexible, high-performance automation that meets the evolving needs of modern manufacturing environments.

The benefits of this integration include:

- Real-time performance

GPU acceleration via NVIDIA Jetson platforms ensures low latency, allowing for responsive perception and precise robotic manipulation in dynamic and demanding conditions. - Ease of deployment

MachineMotion AI simplifies the integration and scalability of advanced robotic functionalities, reducing complexity and setup time for industrial teams. - Remote capabilities

With built-in cellular connectivity, MachineMotion AI enables robust remote monitoring, diagnostics, and software updates, minimizing downtime and enabling continuous system optimization.

Manufacturers and developers seeking to build or scale similar solutions can begin by exploring NVIDIA Isaac Manipulator’s capabilities and referencing Vention’s MachineMotion AI documentation.

As AI-driven robotics continues to advance, this integrated stack lays the foundation for greater adaptability, autonomy, and efficiency, paving the way for widespread adoption of intelligent automation across industries.

More Information

Vention Launches AI-Bin Picking Solution at NVIDIA GTC 2025, Marking New Automation Milestone

Vention, a Canadian company on a mission to democratize automation, marked another milestone on that journey at NVIDIA GTC 2025 with the launch of their AI-powered bin picking solution. Using robots for bin picking is not new. But Vention’s solution breaks the mould with its proprietary intelligence and control technology that enables businesses of all sizes to automate faster than ever. And their AI-driven bin-picking technology is slated for commercialization later this year.