Siemens Drives AI Adoption with Industrial Operations X and NVIDIA-Accelerated Industrial PCs

November 12, 2024

- Siemens’ Industrial Operations X portfolio and NVIDIA GPUs integrated in Siemens IPCs enable advanced AI applications across industries

- Estimated 25-fold acceleration in AI execution with Siemens’ integrated hardware and software enhanced by NVIDIA technology spurs efficiency, agility, and innovation

- Siemens and NVIDIA to present the future of AI in industry at SPS trade show 2024

Siemens, a leading technology company, has announced the launch of a new line of Industrial PCs (IPCs) equipped with NVIDIA’s GPUs. Along with an extended AI offering, that’s part of the Industrial Operations X portfolio, it will accelerate artificial intelligence (AI) applications and mark another milestone in the strategic partnership between Siemens and NVIDIA that was launched in June of 2022.

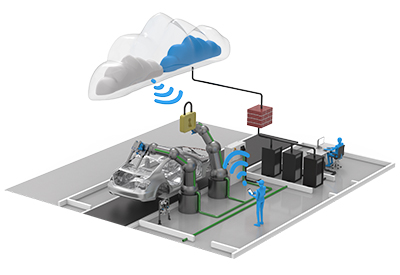

As a result, Siemens can now offer a scalable computing portfolio dedicated to high-performance industrial applications – from rugged Industrial PCs to Industrial Edge Computing. The integration of the full-stack NVIDIA accelerated computing platform allows Siemens IPCs to handle complex AI tasks in advanced industrial automation: for example, AI-based robotics, quality inspection, predictive maintenance, and operational optimization.

The new offering is estimated to bring a 25-fold acceleration in AI execution to the shop floor when using Siemens’ integrated hardware and software enhanced by NVIDIA AI and accelerated computing. This will help drive down costs and accelerate time-to-market for customers.

“Customers driving their digital transformation need high-performance industrial-grade systems. Our new offerings accelerate the next-level AI-based applications,” says Rainer Brehm, CEO of Factory Automation at Siemens. “With Industrial Operations X, we’ve made the latest advances in industrial AI widely available to companies of all sizes.”

Rev Lebaredian, Vice President of Omniverse and Simulation Technology at NVIDIA said: “Supercharged by NVIDIA accelerated computing and AI technologies, Siemens’ leading portfolio of industrial automation solutions will enable the world’s manufacturers to reach new heights of digitalization and deliver incredible efficiencies and agility.”

Supercharging AI applications on the shop floor with Industrial Operations X

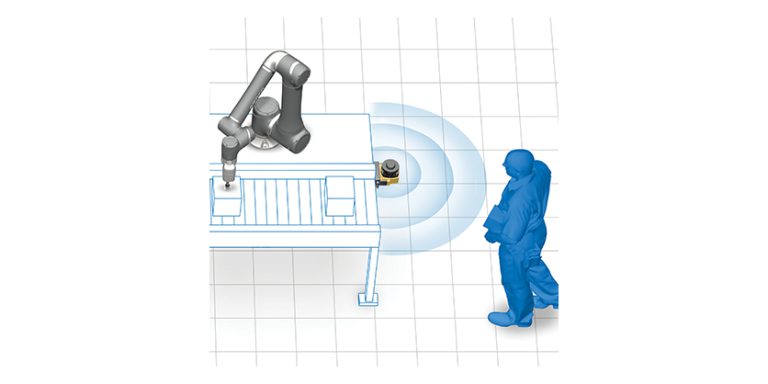

With the increasing integration of AI and machine vision solutions in industrial automation, Siemens and NVIDIA are striving to make AI capabilities accessible to automation engineers without requiring extensive coding knowledge. This will further democratize access to these cutting-edge technologies.

In addition to no-code tools to integrate, manage, and execute industrial AI solutions, the Industrial Operations X portfolio comprises a wide range of out-of-the-box AI applications. For instance, Simatic Robot Pick AI accelerated by NVIDIA enables OT users with no AI expertise to create AI-driven piece-picking robot solutions that meet critical warehouse automation needs. The Siemens Industrial Copilot for Operations powered by NVIDIA NIM microservices also runs entirely on-site and allows automation and maintenance engineers to make real-time queries about operational and document data in order to facilitate rapid decision-making and reduce machine downtime.

Full suite of Siemens IPCs powered by NVIDIA technologies

The newly launched Siemens IPCs are NVIDIA-Certified Systems, meaning that they are ready to deploy the many applications built with NVIDIA NIM microservices and edge AI frameworks, including NVIDIA Isaac ROS, Holoscan, and Metropolis. The IPCs are designed to meet the stringent demands of industrial environments and withstand harsh industrial conditions while maintaining a small footprint, which ensures their reliability and longevity.

New devices include the embedded IPC Simatic BX-35A, a powerful and compact device based on the NVIDIA Jetson Orin NX systems-on-modules (SoMs), for high-performance AI computing in a low-power and fan-less design. Other NVIDIA-powered devices include the Simatic IPC RW-545A (high-performance workstation), Simatic IPC RS-828A (high-performance server for production datacenters), and Simatic IPC BX-59A (high-performance modular Box PC).

The Simatic IPC BX-59A offers a comprehensive end-to-end solution for seamless and high-performance AI integration, management, and execution in industrial environments. Along with the newly released robust AI Inference Server GPU accelerated powered by NVIDIA’s Triton™ Inference Server, customers can deploy and run AI models in industrial environments with no coding expertise. Combining the AI Inference Server GPU accelerated with the Simatic BX-59A as an edge device, Siemens has measured a 25-fold acceleration in AI execution on the shop floor.

All Simatic IPCs can be ordered with Siemens’ Simatic Industrial OS, a real-time Debian-based operating system that comes preinstalled with NVIDIA AI software, enabling rapid deployment of industrial AI applications.

Related Story

Siemens Releases Industrial 5G Router in U.S. Market

The Scalance MUM856-1 – the first industrial 5G router from Siemens – is now available for the U.S. market. The device connects local industrial applications to public 5G and 4G (LTE) mobile wireless networks. The router can be used to remotely monitor and service plants, machines, control elements and other industrial devices via a public 5G network flexibly and with high data transmission rates. Demand for this type of solution is growing in all industries. The device also integrates into private 5G networks. The Scalance MUM856-1 supports future-oriented applications such as mobile robots in manufacturing, autonomous vehicles in logistics or augmented reality applications for service technicians.