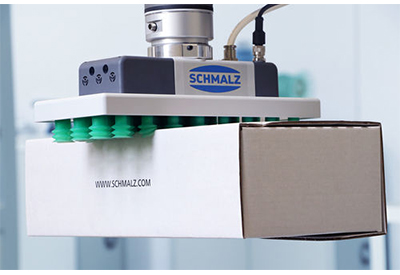

Schmalz: Tolerance to Shape and Size

December 11, 2020

J. Schmalz GmbH has recently developed a new gripper for automated handling: The FQE is suitable for a variety of different tasks, including on collaborative robots, and grips workpieces of varying shapes and sizes with speed and reliability.

This versatile gripper has been developed to pick up workpieces regardless of their shape, size or position. It is ideal for use on collaborative robots or fully automated applications – and is just as suitable for end-of-line packaging in intra-logistics as for delicately gripping products in the automotive, glass or electronics industry.

The new end-of-arm tool features integrated control valves with a suction and blow-off function. They not only enable you to shorten your cycle times, but also help to reduce interference contours. This aspect is also important for human-robot collaboration (HRC): While designing the new gripper, Schmalz focused on rounded edges, an enlarged contact surface and the lowest possible impact forces. As a result, the new gripper complies with ISO TS 15066 and is therefore HRC-capable. At the same time, the lightweight modular design keeps the weight of the FQE so low that it can hold up to 35 kilograms.

The FQE is available in an M version for operation with external vacuum generators and an X version. In the X version, the integrated ecoPump SEP provides the necessary vacuum, making it an energy-efficient and cost-saving solution. A silencer keeps noise to a minimum for staff in the vicinity. As the sealing element, users can choose between foam or suction cups. The gripper is available in the sizes 120 x 60 millimeters, 220 x 80 millimeters and 300 x 130 millimeters.