Programming Robots in Next to No Time: Hand Guiding With KUKA ready2_pilot

February 25, 2021

There are countless application scenarios for the use of robots in companies: welding, drilling and bonding are just three examples of tasks that machines can perform quickly, untiringly and with consistently high quality. At the same time, however, automation also entails digitalization. After all, the use of robots in industry rarely refers to just the machine itself. The robot controller and software are also included. That is precisely where the challenge lies for many companies. According to a study conducted by the industry association Bitkom and the German Confederation of Skilled Crafts (ZDH), while 81 percent of companies asked responded that they are open for innovations, some 64 percent of respondents expressed reservations with regard to digital technologies.

Hand guiding instead of time-consuming programming

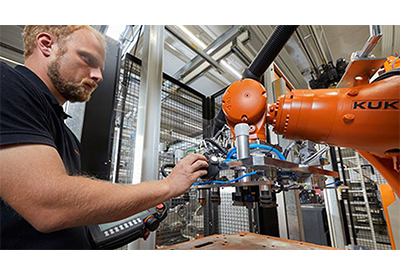

One of the main obstacles preventing robots from becoming more widespread is frequently the aspect of operator control. Potential users believe that they would have to invest heavily in training and personnel and thus frequently reject robotic solutions for this reason. The solution to this challenge is called ready2_pilot from KUKA. In line with the “easy programming” principle, the solution is aimed primarily at companies without particular experience in robot programming.

Hand guiding – teaching the robot by means of manual guidance

The employee guides the robot manually along a workpiece using the “Commander”, a type of 6D mouse, and “shows” it what it is supposed to do. The motions are converted to commands via the wireless connection to the teach pendant; these commands can then be freely modified or added to as required. In this way, tasks can be recorded very quickly by simply moving your hand.

Wireless robot control package: KUKA ready2_pilot

{videobox}8yGaMFDuFbE{/videobox}

Teaching the robot by hand, as if performing the task yourself

The tool used for this is the “Commander”, a control head that is similar to the 6D mouse on the KUKA smartPAD, that can be moved in all directions and also recognizes forward and backward commands. The Commander can be attached directly to the robot in just a few steps and responds very sensitively. In this way, work steps can be performed directly on the workpiece. The major advantage: even people with little experience quickly get used to the robot in this way and simply “give” it tasks without the need for in-depth training or certification. Furthermore, the Commander is multifunctional. It can be used equally with all robot types, so the investment pays for itself very quickly.