Netzer Introduces VLP-60 Two-Plate Ring Absolute Encoder for Harsh Environments

May 3, 2021

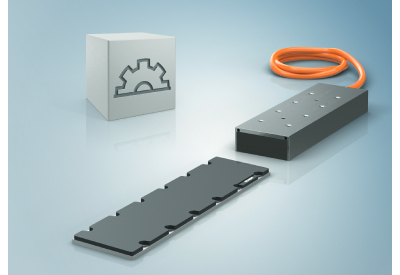

Netzer VLP encoders are ideal for OEM applications. Featuring an open frame, 2 plate design, the sensor is lightweight, highly tolerant to temperature, shock, EMI, RFI and magnetic fields. It offers a unique combination of high performance at an economical cost.

The VLP-60 is a new member of the VLP series of Electric Encoders a product line based on Netzer Precision Motion Sensor proprietary technology. EE products are characterized by features that enable unparalleled performance including:

- – Low profile (<6 mm)

- – Hollow shaft (Stator / Rotor)

- – No bearings or other contact elements

- – High resolution and unparalleled precision

- – Very low weight

- – Digital interfaces for absolute position

- – Extremely low profile & weight

- – Auto calibration option

- – High tolerance to temperature extremes, shock, moisture, EMI, RFI and magnetic fields

The holistic structure of the Electric Encoder makes it unique: Its output reading is the averaged outcome of the entire area of the rotor. This feature allows the EE a tolerant mechanical mounting and to deliver outstanding precision.

Due to the absence of components such as ball bearings, flexible couplers, glass discs, light sources and detectors along with very low power consumption enables the EE to deliver virtually failure-free performance in nearly all types of conditions. The EE output is a digital serial synchronous with absolute position single turn.

This combination of high precision, low profile and, low weight has made Netzer Precision encoders highly reliable and particularly well suited to a wide variety of industrial automation applications.