KNIPEX Tools Introduces New Inserts for Pipe and Connector Pliers Series

March 18, 2021

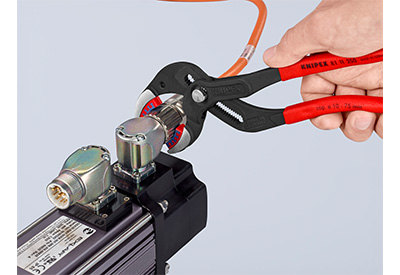

KNIPEX Tools introduced new plastic inserts for its Pipe and Connector Pliers series (81 11 250). The innovative plastic inserts now consist of two component materials: soft blue outer layer and firm red inner layer.

The Pipe and Connector Pliers series is the only tool of its kind to offer 25 easy adjustments with just the push of a button. The Pipe and Connector Pliers feature a sturdy box-joint design. The dual component inserts are designed for gently loosening hoses on nozzles. The pliers include the soft jaw to prevent corrosion by not allowing metal from being transferred onto the workpiece. The soft jaw is an ideal tool for cannon plugs in aviation and electrical connections in high-performance automotive, truck and trailer applications. The rounded jaws grab round pipes and connectors up to 3 5/32 inches in diameter, suitable for tightening and loosening screw connections, plastic pipe fittings and round nuts. The series also includes a version without the plastic inserts if a user needs a tougher grip (81 01 250).

The Pipe and Connector Pliers are forged and oil-hardened out of German, chrome vanadium steel and feature a non-slip plastic coating. The model 81 01 250 has serrated gripping jaws for diameters 1 to 3 5/32 inches, while the model 81 11 250 with replaceable plastic jaws for soft surfaces has diameters from 3/8 to 3 inches.

“By adding the two component materials to the inserts, users get a grip that’s sturdy enough to tackle tough jobs, but gentle enough to protect the workpiece,” said Peter A. Grable, product manager, KNIPEX Tools. “Once this tool is set, it stays in that position without movement until the user changes it, making it the ideal tool for repetitive work.”

For more information, visit www.knipex-tools.com.