Improved Kinova Kortex API Version 3.2: Software Update for Link 6 Collaborative Industrial Robot

The Kinova Kortex API 3.2 is a software development kit (SDK) that allows developers to configure and control Kinova’s Link 6 robotic arm

February 22, 2023

Kinova is pleased to announce the introduction of Kinova Kortex API version 3.2 for their collaborative industrial robot, Link 6! This new version includes a host of new features, enhanced stability, and overall performance improvements.

They have been working hard to ensure that this update provides their users with the greatest possible experience. In this article, they take a deeper look at some of the new features and enhancements in version 3.2. They also provide some tips on how to get the most out of the new version by utilising a variety of new or updated plugins.

Download the latest version Link 6 software update package v3.2.0

High-Level Control in Python

The Kinova Kortex API 3.2 is a software development kit (SDK) that allows developers to configure and control Kinova’s Link 6 robotic arm. The latest release of the Kortex API now includes support for high-level control in the Python programming language, making it even easier for industrial customers to integrate Kinova’s collaborative robots into their operations.

The use of the Python programming language for the Kortex API also offers a number of benefits. Python is a widely-used and easy-to-learn programming language, making it accessible to a wide range of developers.

Learn more at docs.kinovarobotics.com on by checking out our code examples on Github.

New features

Plugins

Release 3.2 is accompanied by many updated plugin functionalities including:

- OnRobot gripper support for RG finger grippers. More to come!

- Robotiq gripper support for Hand-E and 2F familly.

- PLC Fieldbus communication to the robot for Modbus TCP and EtherNet/IP

Find out more by browsing to: Resources – Plugins

Upcoming features:

- Force Seek (search) using the robot’s built-in force-torque sensor

- Execution of Python code in Visual Programming

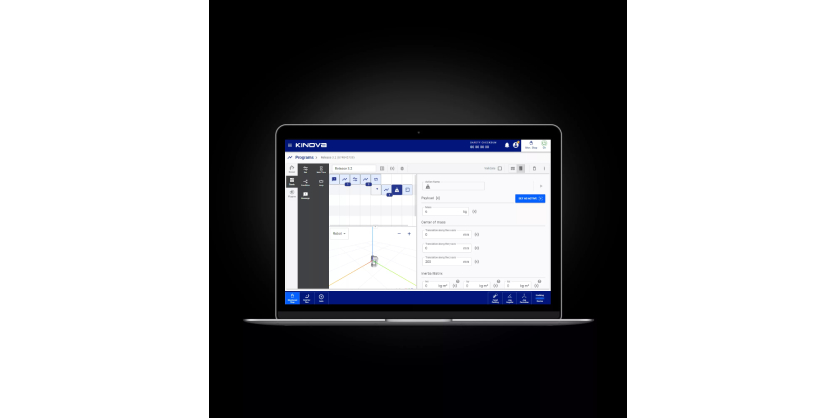

Payload Management in Visual Programming

A new Visual Programming action tile has been added to allow configuration of the robot payload in programs

Maintenance Mode

Additionally, this release includes backup and restore functionality for the robot’s configuration, ensuring that any adjustments made to the robot can be easily saved and restored. This feature makes it easy to maintain your collaborative robot across updates as well as duplicating completed projects

This feature also allows for easy diagnostics and troubleshooting by providing the ability to export logs to get quicker customer support. This version includes other changes such as bug fixes and stability and performance improvements . Review our release notes for more details: Link 6 release notes v3.2.0

Power and Force limitation

This feature enhances the safety of the robot by implementing mechanisms to detect and limit collisions making Kinova’s collaborative robot safer to use in environments where human workers are present. This feature enhances the safety and efficiency of the robot by implementing two key mechanisms: Contact force reduction and Energy limitation. The Contact force reduction feature triggers when a given force is sensed, reducing the amount of force the robot can exert on its surroundings. Energy limitation, on the other hand, saturates the total energy of the system, limiting its speed, ensuring that the robot’s movement stays within safe limits in case a collision is detected.

Please note that it is the responsibility of the integrator to ensure that the robot can safely operate in environments where human workers are present. This includes validating but is not limited to performing a risk assessment and ensuring the robot is integrated in accordance with the applicable safety regulations.

Notice about earlier versions

Kinova is notifying customers of the deprecation of software version 3.0.0, 3.1.0 and 3.1.1. The software components were made available as part of the Early Adopter Program and delivered with the initial product launch. Earlier versions are not recommended for new designs and limited support will be offered. Kinova highly recommends that you upgrade to the latest version, 3.2, at your earliest convenience. If you need assistance in migrating your old configurations or help with the upgrade process, please reach out to their customer support team at support@kinovarobotics.com.

More Information

Related Product

Kinova Launches Link 6 Collaborative Robot

Montreal-based Kinova Robotics has announced the Link 6, a new generation industrial robot created from start to finish in North America, and designed for businesses looking to benefit from automation.

Kinova said Link 6 is Canada’s first industrial collaborative robot, featuring automation solutions to enable greater daily efficiency while also improving the quality and consistency of production results. Launch applications include pick-and-place, part assembly and machine tending, the company added. The Link 6 controller also includes the highest processing power and memory capacity on the market, which makes it ready to use with AI solutions in the future, while keeping the size of the controller compact. Kionva said the robot is developed and designed with any user in mind – from an experienced industrial integrator to an operator with no particular robotic skills.