Comau Unveils “MI.RA/PICKER”, A Fully Automated Perception-Based Random Bin Picking Solution

Comau Unveils “MI.RA/PICKER”, A Fully Automated Perception-Based Random Bin Picking Solution

July 3, 2023

- Autonomously recognizes, locates and grasps randomly placed objects at a rate of up to 40 pieces per minute (PPM)

- Reduces complexity while ensuring optimal picking precision and efficiency for single or multiple bins measuring up to 1 meter tall

- “MI.RA/PICKER” helps increase throughput while reducing upstream process times, saving time, energy and resources

- Comau’s turn-key solution is based on advanced engineering, machine inspection and seamlessly integrated features

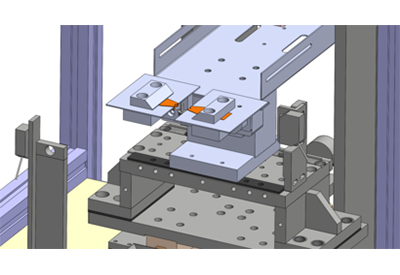

Comau introduces “MI.RA/PICKER”, an intelligent advanced automation solution for perception-based random bin picking. Adaptable to any brand of commercial robot, customized bin or customized gripper, the fully automated picking solution uses two high-resolution laser sensors and a central camera to autonomously recognize, locate and grasp randomly placed objects at a rate of up to 40 pieces per minute (PPM). Furthermore, its streamlined virtual simulation tools and predictive algorithms guarantee optimal path management and collision-free trajectories, for precise and reliable performance while lowering costs and potential risks. All said, the automated picking eliminates the need for unsustainable manual sorting activities, which increases both productivity and operator well-being.

Designed with the support of Comau’s network of technology partners, the turn-key solution combines 3D vision technology, dual sensors and an intuitive programming interface to deliver best-in-class picking precision and efficiency for single or multiple bins containing unorganized rigid parts whose orientation and arrangement is unpredictable. And because products can be dumped into bins instead of placed in an orderly manner, MI.RA/Picker reduces upstream process times while ensuring a simplified logistic flow without singularization of the parts or rigid fixtures.

MI.RA/Picker is the result of Comau’s systems-based approach to flexible automation, which allows the company to develop tailor-made, turn-key solutions using the most suitable equipment for the needs of each specific project. The newest product within Comau’s Machine Inspection Recognition Archetypes (MI.RA) family of hardware-agnostic, intelligent vision systems, MI.RA/Picker represents a concrete, cost-effective answer to automate the complexity of collision-free random bin and piece picking operations. As such, it is perfect for the food & beverage, pharmaceuticals, plastics, electric/ electronics, metal and machinery and automotive industries.

“Comau’s ongoing commitment to shaping innovation through advanced automation is seen in our ability to make complex technology more accessible and effective,” said Nicole Clement, Chief of Advanced Automation Solutions Business Unit. “We believe, based on internal estimates and supporting market research, that the random bin and piece picking market could reach $1.2B by 2025, with a compound annual growth rate of 76% (2019-2025). In this light, our novel approach to intelligent random bin picking for machine tending, pick&place and kitting operations, among others will undoubtedly help our customers increase both their process quality and production capacity.”

Nicole Clement, Chief of Advanced Automation Solutions Business Unit

More Information

Related Product

Flex-BD – Comau is Developing a Fully Automated System for Sustainable Battery Recycling and Second-Life Repurposing

Comau has renewed its commitment to the EU’sFlexible Battery Dismantling (Flex-BD) project for the second year, to help deliver a fundamental pillar on the path towards a truly circular economy.

Flex-BD is a robotized system that automates the entire process of dismantling worn-out electric batteries using a highly flexible, repeatable and standardizable process. Now, having validated the proof-of-concept, Comau has expanded the scope to include second life repurposing of automotive batteries. In doing so, Comau, in collaboration with other partners within the EU EIT Manufacturing community, is taking an important step towards greater sustainability within eMobility.