Playing It Safe in the Assembly of MRI Machines

November 3, 2022

The future belongs to human-robot cooperation. System builder BEC developed such a collaborative solution for Siemens Healthineers. It inserts coils weighing several tonnes precisely into the magnets of magnetic resonance imaging (MRI) machines. Electric cylinders from Festo, which ensure the coils are securely gripped, play a crucial role here.

Hans-Günther Nusseck, project manager at BEC (left), and Timo Kloker, sales engineer at Festo, discussing the use of the Festo electric cylinders in the system

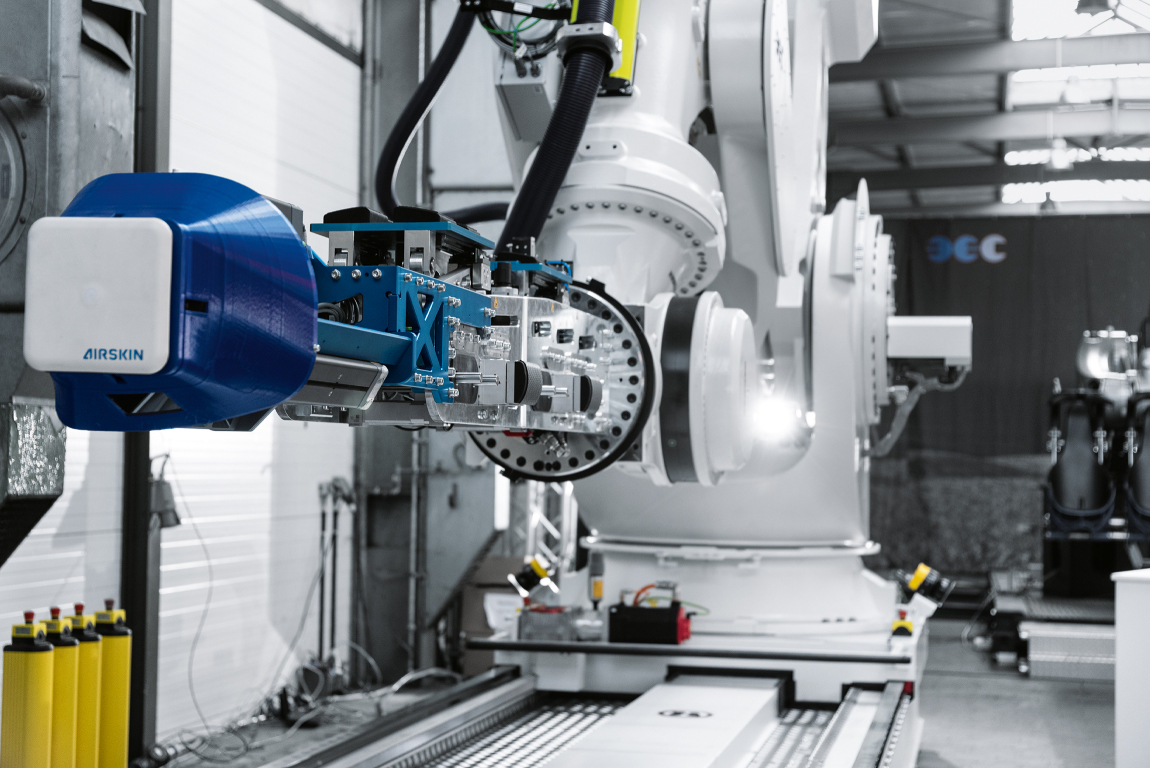

The first thing you notice when entering the BEC assembly hall is one of the world’s biggest articulated arm robots with a load capacity of 2300 kg. It’s like something from aerospace technology, and nothing less than high-tech. Even more eye-catching is the vast gripper system, which BEC has mounted on the robot’s articulated arm. Equipped with 3D scanners and touch-sensitive Airskin sensors, it is truly high-tech. “When the gripper picks up the coils weighing up to 1.5 tonnes and inserts them into the magnets of a future magnetic resonance imaging machine, the utmost precision is required,” emphasises Hans-Günther Nusseck, project manager at BEC.

Precise to half a millimetre

High-tech gripper system on the articulated arm robot. It is vital that the coils do not twist or slip when the gripper picks them up and inserts them into the magnets; the tolerance for inserting the coils into the magnets is no more than 0.5 millimeters

Total precision when handling objects weighing 1.5 tonnes might seem like an impossible task, but it’s all part of BEC’s core competency. “It is vital that the coils do not twist or slip when the gripper picks them up and inserts them into the magnets; the tolerance for inserting the coils into the magnets is no more than 0.5 millimetres,” explains Nusseck.

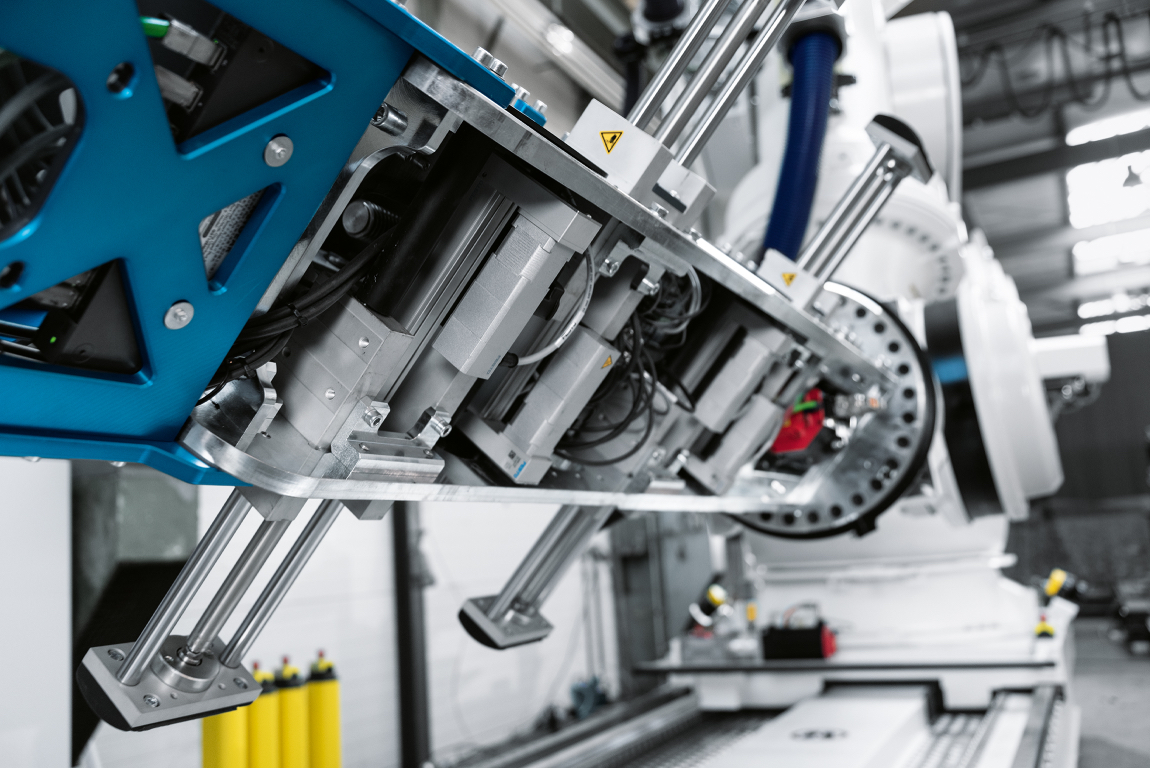

This is precisely the task of four supports driven by electric cylinders EPCC from Festo. After entering the coil, the electric cylinders guide the supports against the inner wall of the coil. “The electric cylinders from Festo have proven to be the right choice. They have a compact design, but at the same time provide a large working area and thus have the necessary flexibility for 13 different coil dimensions,” says automation expert Nusseck.

Powerful and gentle at the same time

Flexible, robust and precise: the supports with electric cylinders from Festo need to be powerful enough to be able to hold the coils weighing up to 1.5 tonnes, but at the same time not so powerful that they damage them

The supports need to be powerful enough to be able to hold the coils weighing up to 1.5 tonnes, but at the same time not so powerful that they damage them. “The Festo electric cylinders do an excellent job here,” emphasises Nusseck. On a practical note, the drive amplifiers, in this case the servo drives CMMT-ST, are mounted on the robot itself, rather than on the gripper system. “This frees up space on the gripper and makes it less complicated,” reports Nusseck.

Thanks to the compact ball screw drive, the electric cylinder EPCC guarantees quiet operation and precise positioning. Low internal friction ensures short positioning times and a high dynamic response. It is available in four sizes with a non-rotating piston rod, a stroke of up to 500 mm and a plain bearing guide, and includes life-time lubrication for a long service life. The integrated coupling and double bearing make for a compact design. The motor can be mounted in an axial or parallel position, and this can be changed at any time.

The servo drive CMMT-ST has a PROFINET interface for easy integration into existing control systems. “We started working with Festo right from the initial phase of the project to make sure that the drives were designed, sized and commissioned efficiently and matched the overall system,” explains Nusseck.

Free and safe movement in the workspace

Practical: the drive amplifiers, in this case the servo drives CMMT-ST, are mounted on the robot itself, rather than on the gripper system. This frees up space on the gripper and makes it less complicated

Siemens Healthineers uses the system to assemble its MRI machines. It makes the process steps involved in inserting the coils into a magnet significantly safer and more efficient. The real highlight, however, is that the system’s process steps with the articulated arm robot are automated. Thanks to sensor technology with 3D scanners and touch-sensitive Airskin sensors, the system moves freely and safely in the workspace as a collaborative human-robot solution. As a result, there is no need for a safety fence. The role of people consists solely of monitoring this first step in the production of an MRI machine. The sensors in the system ensure safety.

“It is precisely this human-robot cooperation that we consider to be our USP,” explains Nusseck. He also mentions other applications in medical technology where BEC systems are used, such as in radiation therapy for the highly precise positioning of patients at the radiation source, or a robot with seats on an articulated arm that simulates riding a roller-coaster.

Source