Guide to Mechatronics – Part 8: Future Innovations

March 5, 2025

The future of mechatronics is closely intertwined with the advancement of emerging technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and machine learning. These technologies are not only enhancing the capabilities of mechatronic systems but are also opening new possibilities and applications.

Artificial Intelligence (AI):

AI’s integration into mechatronic systems has led to smarter and more autonomous systems capable of making complex decisions and learning from their environment.

- Predictive Maintenance: AI algorithms can analyze data from machine sensors to predict failures before they occur, reducing downtime and maintenance costs.

- Enhanced Decision-Making: AI enables mechatronic systems to make real-time decisions based on a wide array of inputs, improving the efficiency and effectiveness of systems like autonomous vehicles and smart manufacturing processes.

Internet of Things (IoT):

IoT extends the capabilities of mechatronic systems by connecting them to a network, allowing for remote monitoring, control, and data analysis.

- Smart Grids: In energy management, IoT-enabled mechatronic systems can optimize the distribution and use of electricity in real time, leading to more efficient and sustainable energy use.

- Connected Devices: In consumer markets, IoT-connected mechatronic devices, like smart home appliances, offer enhanced user experiences through remote control and customization.

Machine Learning:

Machine learning algorithms enable mechatronic systems to adapt and improve over time based on data patterns, leading to more intelligent and efficient operations.

- Robotics: Advanced robotics utilizes machine learning for better object recognition, environmental interaction, and autonomous navigation.

- Process Optimization: In manufacturing, machine learning algorithms analyze production data to optimize processes for increased efficiency and reduced waste.

The integration of these emerging technologies into mechatronic systems is not without its challenges. It requires sophisticated software algorithms, robust data infrastructure, and enhanced security measures to protect against cyber threats.

However, the potential benefits in terms of efficiency, adaptability, and intelligence make this a key area of focus for the future development of mechatronics.

As AI, IoT, and machine learning continue to evolve, they will undoubtedly open new frontiers in mechatronics, leading to systems that are more connected, responsive, and capable of autonomous operation.

This integration signifies a leap towards a future where mechatronic systems are not only tools but intelligent partners in industry, healthcare, and daily life.

This article is original content created and posted by Electromate. Please do not re-post this content without prior approval from Electromate.

Related Stories – A Guide to Mechatronics

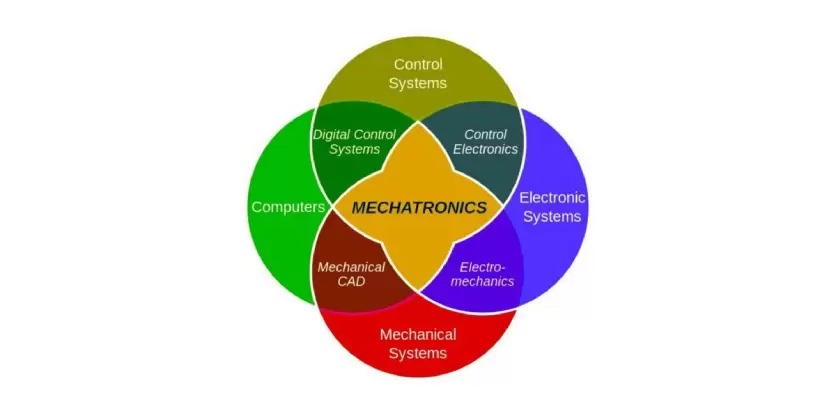

Part 1: Introduction & Fundamentals

Part 2: Composition of a Mechatronic Subsystem

Part 3: Strategies for Integrating Mechatronic Subsystems

Part 4: Software & Programming

Part 5: Tools & Languages in Mechatronics Software Development