Siemens Presents €2 Billion Investment Strategy to Boost Future Growth, Innovation and Resilience

June 26, 2023

- Ramp up of global investment in new high-tech factories, innovation labs and education centers to expand leadership in digitalization, automation and sustainability

- Total investments of €2 billion mainly in manufacturing capacity expansion to be disclosed this year

- Following investments in Germany and in the U.S., Siemens expands its production network and R&D capacities in Asia

- New high-tech factory in Singapore announced today to serve growing markets in Southeast Asia

- Expansion of digital factory in Chengdu to boost further growth in China

- Additional investments in Europe and U.S. to be announced

To boost future growth, drive innovation and increase resilience, Siemens presented its investment strategy which includes €2 billion mainly for new manufacturing capacity as well as innovation labs, education centers and other own sites. Siemens announced a new high-tech factory in Singapore, to serve the booming Southeast Asia markets.

“Our technologies address secular growth trends where our customers need our support to become more competitive, resilient and sustainable. Siemens is experiencing significantly above-market growth. Today we announce an investment strategy to boost future growth, drive innovation and increase resilience,” said Roland Busch, President and Chief Executive Officer of Siemens AG.

“The investments underpin our strategy of combining the real and the digital worlds – as well as our focus on diversification and local-for-local business. We are clearly doubling down on our strong global presence to support growth in the most relevant markets in the world.”

Roland Busch, President and Chief Executive Officer of Siemens AG

In addition, there is an expected increase of around €0.5 billion in research and development (R&D), such as artificial intelligence and the industrial metaverse, in fiscal year 2023 versus prior year. This R&D is focused on strengthening Siemens’ leading position in core technologies including simulation, digital twins, artificial intelligence or power electronics, as well as supporting the development of the Siemens Xcelerator open digital business platform. The company recently announced a partnership with Microsoft to speed up code generation for industry automation by using ChatGPT. With NVIDIA, Siemens is working to build the industrial metaverse to improve design, planning, production and operation of factories and infrastructures.

New and additional capacities in Southeast Asia

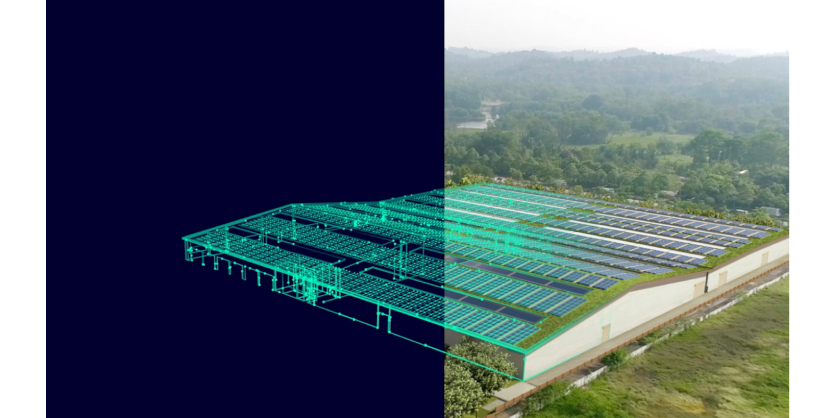

To meet growing demand in Southeast Asia, Siemens announced an entirely new high-tech factory in Singapore, which will be developed using Siemens’ own leading digital twin and innovative, intelligent hardware technologies. Investment in the factory will be around €200 million. The plant will set a new standard for connectivity to showcase the possibilities of digitalization, as well as incorporating highly-automated manufacturing processes. The investment will create over 400 jobs.

All-regions strategy with wave of global investments

As part of its investment strategy and fast-growing business in China, Siemens will also expand its digital factory in Chengdu to serve the local growth opportunities in China for China, investing €140 million (RMB 1.1bn) and creating 400 new jobs. Many of Siemens’ Chinese customers are early adopters of new technologies especially in digitalization and high-tech manufacturing. This is why Siemens also announced the investment in a new digital R&D Innovation Center in Shenzhen to speed up development of motion control systems with digitalization and power electronics technology. The Siemens Xcelerator open digital business platform was launched in China in November 2022.

Series of announcements

Earlier this year, Siemens committed to expand production in Trutnov, Czech Republic, to enhance capacity at its WEF Global Lighthouse Factory in Amberg, Germany. Moreover, Siemens invests €30 million to expand its switchgear plant in Frankfurt-Fechenheim, Germany, while Siemens Mobility recently announced spending $220 million to build a new rolling stock factory in Lexington, North Carolina, to meet growing demand for passenger trains in the United States. The plant will create more than 500 jobs by 2028.

The planned €2 billion investments and expected increase of around €0.5 billion in research and development include Siemens Healthineers.

Related Story

Simon Fraser University Becomes Global Instructor Training Facility for Siemens Mechatronic Systems Certification Program

Responding to a growing need for training in automation systems in Canada and globally, Siemens and Simon Fraser University (SFU) have announced that SFU is the first and only training facility for instructors delivering the globally recognized Level 3 Siemens Mechatronic Systems Certification program (SMSCP).