Humber’s Recycling Robot Introducing the Next Generation to STEM

March 28, 2023

Humber’s recycling robot introducing the next generation to STEM. Humber College students have built and programmed a robot that can sort recycling materials and are using it to get the next generation interested in technology.

The robot sorts recycled materials such as metal and plastic from a bin and utilizes a 3D camera supplied by SICK Canada, which belongs to the Barrett Centre for Technology Innovation’s (Barrett CTI) Advanced Manufacturing Skills Consortium.

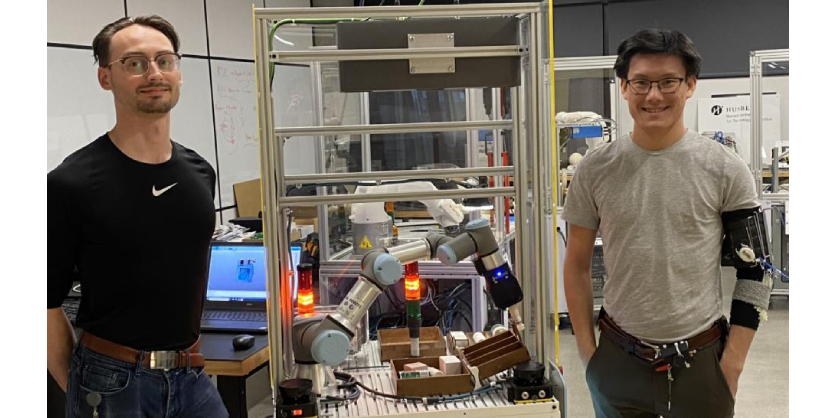

Mateusz Cwalinski, a Skills coach and technology developer at Humber, and Dillon Kong, an Electromechanical Engineering Technology student and Skills competitor, worked on the robot along with former student and current technology developer Nickolas de Boer.

While Cwalinski and Kong see real-world applications for the recycling robot, for now it has another purpose – introducing youth to technology and getting them interested in STEM. To stimulate the young minds, the youth are encouraged to race against the robot in sorting material.

“It’s a great way to get kids into STEM and robotics,” said Cwalinski. “We want them to see that robotics doesn’t have to be intimidating and show them in a simple but fun way.”

Mateusz Cwalinski, aSkills Coach and Technology Developer at Humber

Cwalinski said there’s often a perception that engineering can’t be exciting and they hope the recycling robot helps fight that belief.

“Engineering is a lot of hard work but it can also be rather fulfilling,” said Kong.

Dillon Kong, Electromechanical Engineering Technology Student and Skills Competitor

The way the robot works is the 3D camera takes a photo of the object and compares it to CAD models it has stored on file along with other characteristics. It then places the items – a tin, pill bottle and two different sized boxes – into their respective categories of either paper, plastic or metal.

More Applications for the Humber Recycling Robot

Kong, who was responsible for most of the recycling robot’s programming, decided to take part in the project due to his interest in Skills competitions and wanting to learn more about the technology.

Both Kong and Cwalinski see potential for the technology to become more commonly used. For example, this system works in darkness and not all systems do. Also, items that other systems can’t sort due to their colour can be sorted with the Humber recycling robot.

Cwalinski said the technology is an excellent showcase of the skills of Humber’s students and staff and provides a snapshot of what future Humber students may be able to accomplish and build upon in their own studies.

More Information

Related Story

Humber Students Win Intra-Provincial Mechatronics Skills Competition

Seven teams of students raced against the clock to build automation factories and production systems and demonstrate their skills in automation, mechanical building, electrical wiring, troubleshooting, speed execution, PLC programming, and professional practice. Every team showed confidence and cooperation, and of the 14 students who competed, three were women, showing a presence of women in STEM (Science, Technology, Engineering, and Mathematics).