Engineering Students Explore Advanced Manufacturing Solutions at Omron Proof of Concept Centre

April 23, 2024

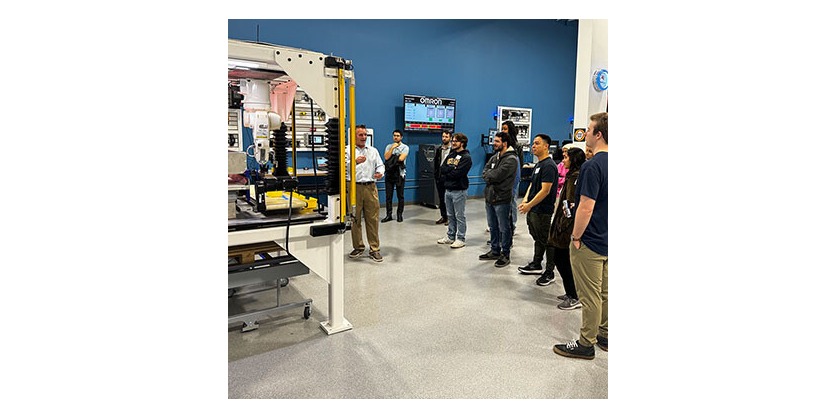

University of Michigan-Dearborn engineering students explore advanced manufacturing solutions at Omron’s Poof of Concept Centre, showcasing the strong partnership between the University and Omron.

A group of engineering students from the University of Michigan–Dearborn recently had the unique opportunity to visit Omron’s Detroit Proof of Concept Center (PoCC). Hosted by the assistant director of CECS Engineering Experiential Learning at UM-Dearborn, the students were given a firsthand experience of Omron’s cutting-edge traceability 4.0 demonstration. This immersive visit provided valuable insights into the benefits of advanced quality and traceability solutions in the manufacturing industry.

Engaging Q&A Session

Following the tour, the students had the opportunity to engage in a Q&A session with Omron’s application engineers, as well as a robotics application engineer. This session provided a platform for the students to ask questions and gain deeper insights into the practical applications of Omron’s technologies in real-world scenarios.

Insights from Industry Experts

To further enrich the students’ understanding of Omron’s advanced manufacturing solutions, the global account manager for the automotive industry will deliver an overview of the company and its expertise in Electric Vehicle (EV) advanced manufacturing solutions. This presentation sheds light on Omron’s commitment to innovation and its contributions to the automotive industry.

Additionally, account managers shared their experiences as participants in the Sakura Trainee Program. Notably, some of them are alumni of UM-Dearborn, highlighting the long-standing relationship between the university and Omron.

A Strong Partnership

The visit by UM-Dearborn students to Omron’s PoCC is just one example of the strong partnership between the university and the company. In fact, the Omron Foundation has made significant contributions to the university, including the donation of a million-dollar robotics lab and the establishment of an undergraduate scholarship endowment. This partnership underscores Omron’s commitment to fostering education and supporting the development of future engineering talent.

Conclusion

The visit to Omron’s Detroit Proof of Concept Center provided UM-Dearborn engineering students with a unique opportunity to witness the practical applications of advanced manufacturing solutions. Through the hands-on traceability 4.0 demonstration and engaging discussions with industry experts, the students gained valuable insights into the benefits of advanced quality control and traceability in the manufacturing industry. This visit further solidified the strong partnership between UM-Dearborn and Omron, highlighting the company’s commitment to innovation and education.

More Information

Learn more about Omron’s Proof of Concept Centres

Related Story

Omron’ Advanced Safety Services 101

Did you know that Omron’s safety training and services encompass safety compliance education, risk assessment, and compliance reviews led by certified safety engineers? Their enabling technologies Include Functional Safety Training, Machine Safety Risk Assessments, Machine Safeguarding Solutions, Lockout/Tagout Procedures, Arc Flash Assessment, And Machine Safety. In this blog, Omron experts provide details about how they can help businesses safeguard workers, maintain stable operations, and prolong equipment life cycles.