ABB Opens Expanded Electrical Products Manufacturing Facility in Pointe-Claire Canada

September 16, 2024

- Investment of US$12M doubles production capacity of high-demand electrical products used across North America

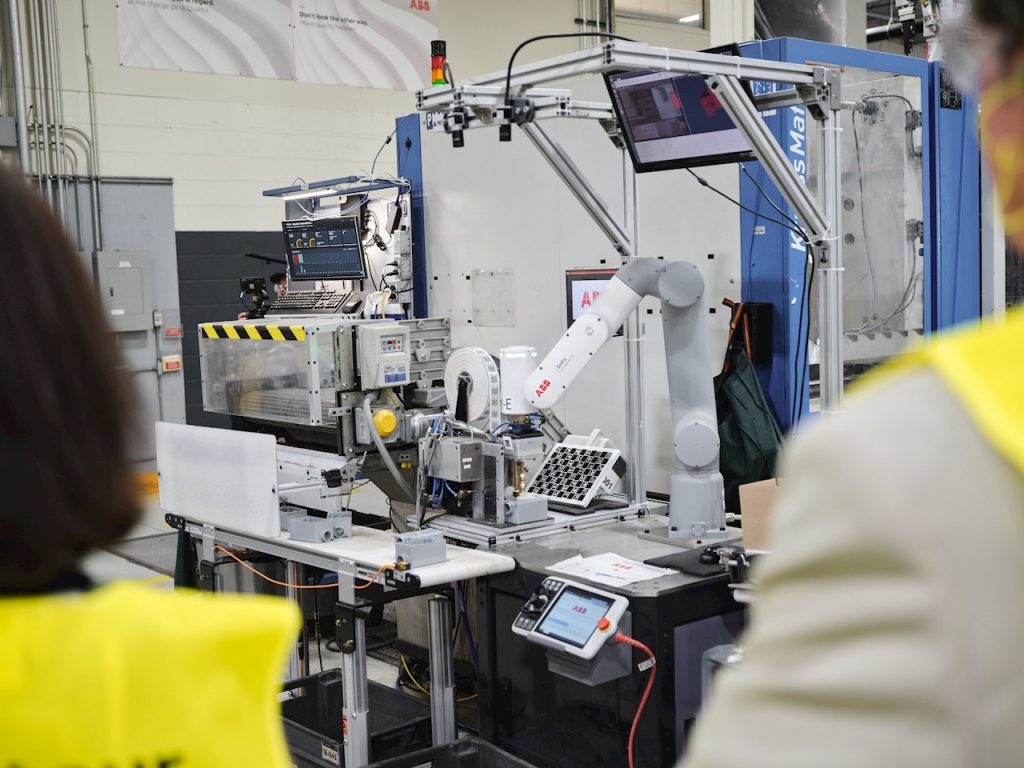

- Adds more than 40 new jobs and ABB collaborative robots to boost region’s manufacturing capabilities

- Sustainability initiatives further reduce energy use and greenhouse gas emissions across ABB’s global operations

ABB’s Installation Products Division in Canada opened its newly expanded electrification products manufacturing facility in Pointe-Claire, Quebec on September 16, 2024. In addition to nearly doubling the size of the facility, ABB’s US$12 million investment creates 40 full-time jobs and doubles production capacity to help meet growing demand for electrical solutions used across North America.

The upgraded 65,000 square-foot facility integrates ABB cobots and advanced technology, as well as flexible automation to boost manufacturing of multiple product lines, including Marrette® wire connectors, Carlon® electrical boxes and fittings, NuTek® non-metallic boxes, Snap-it® fittings, and other components used in a range of Canadian solutions. Digital processes will help increase production and enhance efficiency and sustainability throughout facility, including ABB Ability™, an intelligent energy management solution that uses smart sensors to optimize the plant’s energy use. The expanded site will also include electric vehicle charging stations, solar thermal panels and an electric heat pump to help reduce greenhouse gas emissions of 40% by 2025.

“Growing our footprint in Canada with this state-of-the-art facility builds on our global strategy to regionalize production of essential electrical solutions and expand ABB’s manufacturing capabilities and supply chain,” said Khalid Mandri, President, ABB Installation Products Division. “The digital and robotics technology and sustainability initiatives we have integrated in our expanded plant will help preserve resources and drive efficient, modern industrial production that positions us to keep pace with future demand.”

The investment in Pointe-Claire, Canada is part of more than US$165 million in ABB Installation Products global expansions and improvements since 2020 to increase manufacturing capacity, drive innovation and sustainability, and bring needed products closer to customers, suppliers and distribution partners.

“Doubling our production capacity at this site and growing our team by 50%, in a community where we have operated for nearly a century, is an important milestone in advancing our manufacturing capabilities and reinforcing our commitment to support the future of our industry and Canada’s economic development,“ said Mike Shenouda, Canada Region Leader, ABB Electrification, Installation Products Division.

Integrating ABB cobots at the facility located at 4025 Trans-Canada Hwy helps automate repetitive tasks such as packaging, enabling employees to focus on more strategic and complex work like quality control and systems monitoring.

“We ensure team members are well prepared to work with automated systems through comprehensive training programs on-site and at our dedicated Canadian robotics training facility, including shadowing experienced operators to learn best practices and safety protocols,” said Nicolas Durand, Vice President and General Manager, Robotics, ABB Canada.

In Canada, ABB has a strong history of excellence stretching back more than 100 years. With its Canadian corporate headquarters in Montreal, ABB’s success is driven by 3,200 talented employees in 33 locations from coast-to-coast.

Building on its long history of pioneering in electrification, ABB Installation Products creates solutions to safely connect and protect electrical systems that power businesses, cities, homes and transportation. With more than 200,000 products under 38 premium brand names, ABB Installation Products, formerly Thomas & Betts, solutions are found wherever electricity is used around the world and in space.

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on over 140 years of excellence, ABB’s more than 105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

Related Story

ABB Breaks Ground on A Canadian Installation Products Division Facility

As a next step to the previously announced $16 million investment, ABB in Canada breaks ground for the expansion of its Installation Products plant in Pointe-Claire, Quebec. The facility will expand by 30,000 square feet to 65,000 square feet and once completed in 2024 will create 40+ new jobs.

Increased production capacity will better meet Canada’s growing demand for safe, smart and sustainable electrification solutions.