With Smart MechatroniX, Bosch Rexroth Offers New Solutions for the Factory of the Future

January 4, 2021

With the new Smart MechatroniX solution platform which combines best-in-class linear motion technology components with electronics and software, Bosch Rexroth is responding to market trends in factory automation on the way to the Factory of the Future. The resulting solutions can be used in a wide range of areas. Not only do they allow quick commissioning – they also offer full process transparency and ensure a short time-to-market and high productivity.

As a supplier of linear motion technology and mechatronic systems, Bosch Rexroth has always been close to its customers and knows their requirements. The new solutions impress with their simplicity and travel speed – from development to the start of production – as well as their high performance and sustainability in use. They are also modular and designed to be retrofittable. This allows long-term, flexible and efficient use of the durable components.

One platform, numerous smart solutions

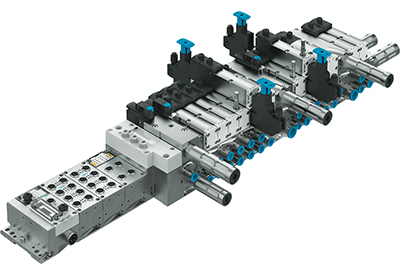

The new Smart Function Kits offer quick and intuitive commissioning and configuration for a range of processes such as joining, pressing or handling. They work according to the plug and produce principle by combining preselected mechanical and electronic components with software. Bosch Rexroth presented the first smart mechatronic solution at Hannover Messe in 2019: the Smart Function Kit for pressing and joining applications. This modular toolbox consists of an electromechanical cylinder, a force sensor, a motor, servo drive, a motion control as well as a software package that enables intuitive commissioning and operation as well as comprehensive process analysis.

The second solution package – the Smart Function Kit for handling tasks – is currently being prepared. It is a single or multi-axis system with innovative control technology and preinstalled software. This kit is suitable for a range of handling tasks where components or work pieces have to be moved precisely and reliably within a defined space. Here too, plug and produce is possible thanks to the associated software package.

Other advantages of the Smart Function Kits include easy product selection and dimensioning via the LinSelect tool as well as quick online configuration and ordering.

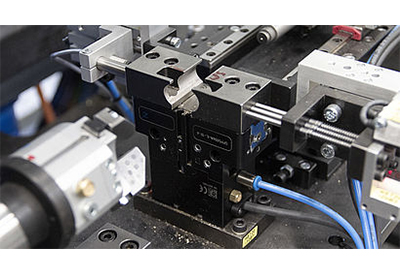

Another Smart MechatroniX solution which is currently being developed is a compensation module with an active measuring function in six degrees of freedom. It increases the precision of handling robots for example and opens up new areas of use for robots and Cartesian systems. The so-called Smart Flex Effector can be used in numerous applications, for example when it comes to joining small tolerances, quality documentation, Tool Center Point detection or compensation of position drifts in the x-, y- and z-direction.

“All these new products and solutions are our contribution towards the Factory of the Future. Bearing in mind the needs of our customers, we’re using entirely new approaches in order to meet current and future requirements in factory automation,” said Dr. Simon Hertenberger, Head of the Mechatronics product department within the Linear Motion Technology division, Bosch Rexroth AG.