WAGO Broadens Power Distribution Terminal Block Line

November 18, 2025

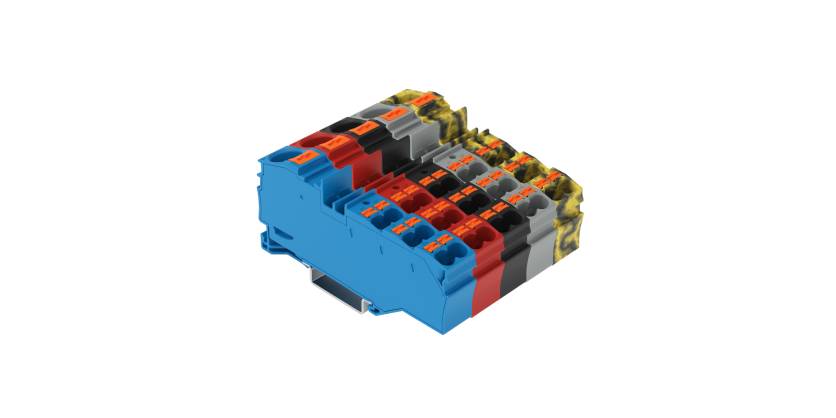

WAGO, the innovator of spring pressure connection technology, has expanded its TOPJOB® S Power Distribution Terminal Block portfolio.

The newest addition features a 4 AWG input in a 0.5-inch compact design, significantly reducing the required footprint on the DIN rail. Both the 2216 and 2016 Series are UL 1059 certified and rated for 70 A / 600 V applications.

Additional advantages include a built-in metre-lead test port for touch-safe troubleshooting, moulded conductor entry markings for easy identification, and compatibility with 2004 Series TOPJOB® S Push-in Jumper Bars for scalable and flexible distribution.

Features & Benefits

- Integrated End Plates: Simplify design and integration

- Compact Footprint: Maximize enclosure space and reduce overall system cost

- Moulded Conductor Entry Marking: Reduce installation errors and commissioning time

- Touch-safe Design with Built-in Test Ports: Increase safety and simplify troubleshooting

- Push-In CAGE CLAMP® Spring Pressure Technology: Reduce wiring time, ensure vibration-proof connections, and eliminate torque requirements

- Multiple Colour Variations: Improve field identification and support design flexibility

- Multiple Color Variations: Easy field identification and design flexibility

This product incorporates conductor terminals using Push-in CAGE CLAMP® technology: WAGO’s universal, maintenance-free connection solution for all conductor types. A key advantage of Push-in CAGE CLAMP® is that it allows the direct insertion of both solid and fine-stranded conductors with ferrules, without requiring tools. No additional preparation is needed; for example, crimping the ferrule is not required.

This distribution terminal block supports 0.5 mm² to 10 mm² conductors on one side and 0.25 mm² to 2.5 mm² conductors on the other.

About WAGO:

Innovation is at the heart of everything we do at WAGO. From our pioneering CAGE CLAMP® spring pressure connection technology to our extensive range of Interconnect, Interface and Automation solutions, such as the fieldbus independent WAGO-I/O-SYSTEM, our customers count on the unconditional performance and reliability of our products to ensure the safe, efficient operation of their systems every time.

More Information

To learn more, go to Distribution terminal block

For additional information, visit www.wago.ca. Contact them at 1-888-WAGO-221 (9246-221) or email customerservice.ca@wago.com.

Related Product

WAGO Expands 750 Series with New Functional Safety I/O Modules

WAGO is introducing three functional safety I/O modules to be used with their PFC controllers. These new 750 Series modules have four safe inputs along with either two safe outputs at 10 A/24 VDC, or four safe outputs at 2 A/24 VDC each. The power outputs operate in both bipolar (high-side/low-side switching) and unipolar (common potential on one side of the load) modes. The module monitors short circuits, cross circuits, and 24 V power supply from separate sources.