The New ODT3CL1-2M Laser Diffuse Sensor: A Real Marvel When it Comes to Distance

February 13,2024

Small housing, big operating range: Thanks to TOF technology, the new ODT3CL1-2M compact diffuse sensor from Leuze achieves an operating range of up to two meters. The 2-in-1 sensor detects the presence of objects and at the same time transmits measurement values.

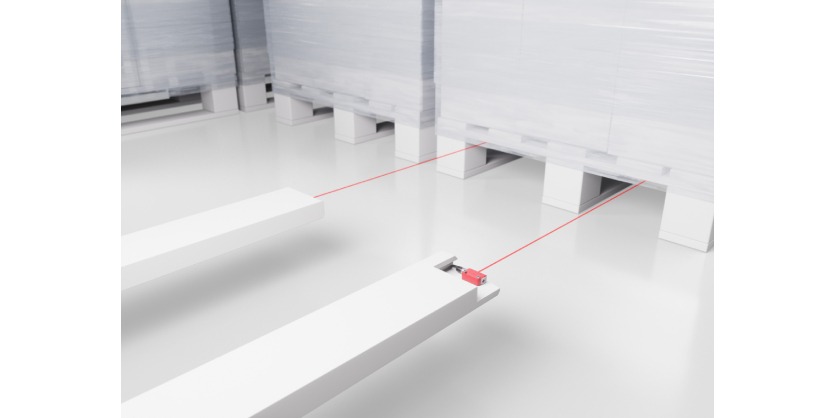

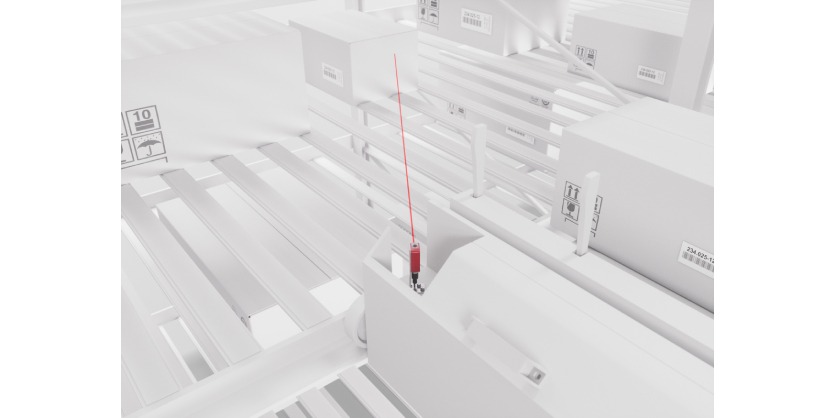

With the new ODT3CL1-2M laser diffuse sensor, the Sensor People from Leuze are extending the operating range of their 3C series distance sensors. Thanks to innovative time-of-flight (TOF) technology, the switching and measuring sensor with background suppression works with an operating range of up to two meters. This makes the ODT3CL1-2M suitable for all applications in intralogistics where long distances need to be bridged: e.g. in automated guided vehicles for monitoring the position of goods, for controlling robot grippers or in quality control. Reliable use is guaranteed even under harsh conditions. This is because the sensor satisfies the high requirements of degree of protection IP69K.

Practical 2-in-1 solution

As a 2-in-1 solution, the ODT3CL1-2M reduces the cost and effort for users in terms of procurement, installation, commissioning and in operation. With its two independent switching points, it is able to perform detection and measurement tasks at the same time. System operators can therefore solve both requirements using just one sensor. This is an advantage if, for example, shuttles are used: They can optimally set and vary their speed via the independent switching points. This enables goods to be transported quickly to their target position.

Everything in view via IO-Link

IO-Link can be used to transmit measurement values and process data of the sensor to the machine control. This allows users to effortlessly evaluate the comprehensive diagnostic data from the diffuse sensor – e.g. temperature information, information on signal quality and warnings. It also makes device swap-out easy: The presettings are transferred to the new device loss-free via IO-Link without the sensor having to be taught in again.

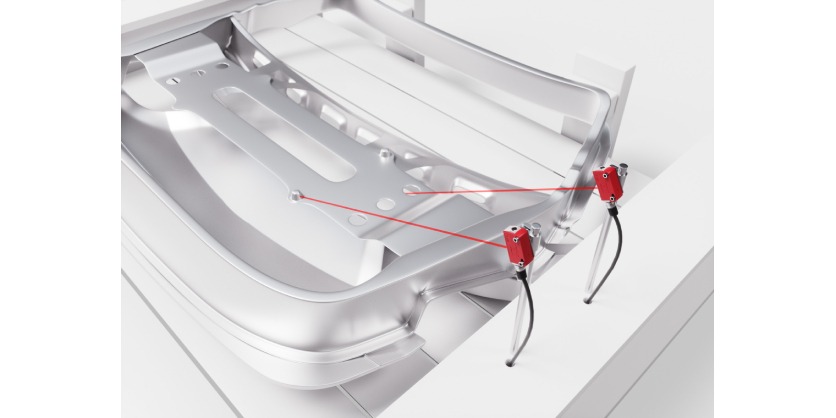

Fits in any space

Thanks to its compact design (11.4 x 34.2 x 18.3 millimeters; W x H x L), the ODT3CL1-2M laser diffuse sensor can also be used where space is limited. For example, it can be used in the gripper of a robot arm, on shuttles or stacker cranes. The small, clearly visible light spot allows fast alignment during commissioning. The operating range can be set numerically via IO-Link. Another advantage of the diffuse sensor is its integrated object test. This allows the function reserve to be quickly checked.

3C series: for any operating range

With the 3C series, Leuze provides a sensor solution that is also suitable for distances of less than two meters. The ODT3C diffuse sensor is therefore ideal for operating ranges up to 150 millimeters – perfect for packaging processes, for example.

Related Story

New Leuze Location in the USA

Duluth in the northeast of Atlanta, Georgia, will in the future be the new Leuze location in the USA. “After careful consideration, we have decided to move our office to a new, more modern and more spacious US location,” says Ibrahim Zuva, VP Operations and Technology Americas. This decision is consistent with Leuze’s long-term strategic growth targets. “The new location also provides a more favorable environment for cooperation with our customers, distributors and partners,” emphasizes Zuva.