Sysmac Automation Platform

January 20, 2021

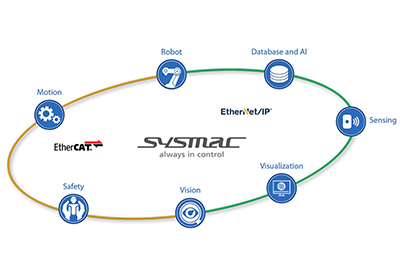

Omron’s Sysmac Platform offers synchronous control of all machine devices and advanced functionality such as motion, robotics and database connectivity. This multidisciplinary concept allows you to simplify solution architecture, reduce programming and optimize productivity.

Why Sysmac?

Omron’s Sysmac Platform makes efficient, flexible and cost-effective manufacturing possible. It features:

- – One control for the entire machine or process

- – Open communication and programming standards

- – Joins EtherNet/IP for factory automation network with the best Ethernet-based machine control network, EtherCAT

- – True Integrated Development Environment (IDE) to simplify all of the disciplines of automation in one place-motion, sequencing, safety, networking, vision inspection, and IIoT

- – Synchronous control for machine performance and time series data collection for IIoT applications

One Controller

The NJ/NX/NY Controller is at the heart of the Sysmac platform. Designed to meet extreme requirements in logic sequence and motion control speed with accuracy. Standard programming and open networks.

One Connection

The Sysmac platform is built on two open industrial ethernet protocols: EtherCAT and EtherNet/IP, providing the perfect match between fast, real-time machine control and data plant management.

One Software

Created to give you complete control over your automation system, Sysmac Studio integrates configuration, programming and monitoring. Graphics-oriented configuration allows quick set-up.