Siemens Revolutionizes Machining Robotics with Danobat and Autonox by Introducing the Sinumerik Machine Tool Robot

March 3, 2025

- Redefining precision: The Siemens Sinumerik Machine Tool Robot offers up to 300 percent better path accuracy for demanding manufacturing processes

- Increased productivity and flexibility: Innovative control concepts enable productivity increases of up to 40 percent and reveal new application areas

- Strong partnerships: autonox and Danobat are the first partners to integrate the Sinumerik Machine Tool Robot into their high-precision robotic solutions

Siemens is bringing its latest innovation in industrial robotics to the market: the Sinumerik Machine Tool Robot (MTR). This groundbreaking technology is a significant advance in the precision and productivity of robots that will open the door to new applications in the manufacturing industry.

The Sinumerik Machine Tool Robot from Siemens is expanding the already successful Sinumerik Run MyRobot /Direct Control solution with new functions and robot types. The Sinumerik MTR enables a quantum leap in accuracy and productivity across the entire workspace. MTR is based on an intelligent control concept that gives industrial robots the characteristics of machine tools. This supports high-precision path applications, even when machining hard materials like steel, whose toughness calls for increased cutting forces and more damping.

Compared to conventional industrial robots, the Sinumerik MTR overcomes these challenges with a 200 to 300 percent increase in path accuracy and significantly higher dynamic rigidity. These characteristics make the Sinumerik MTR ideal for industries like aerospace, defense, and automotive and many other high-precision robotic applications, including post-processing of 3D-printed metal parts.

In addition to improved accuracy, the new control concept brings a 20 to 40 percent productivity increase. This makes the Sinumerik MTR especially attractive for applications that don’t employ process forces, including waterjet and laser cutting. The Sinumerik MTR is controlled by Sinumerik One, the digital native CNC from Siemens. Thanks to its digital twin, it is the key element in digital transformation and helps to simulate and test workflows in a completely virtual environment. Sinumerik One is part of Siemens Xcelerator, the open, digital business platform from Siemens.

The first partners to integrate the MTR into their robots are autonox and Danobat.

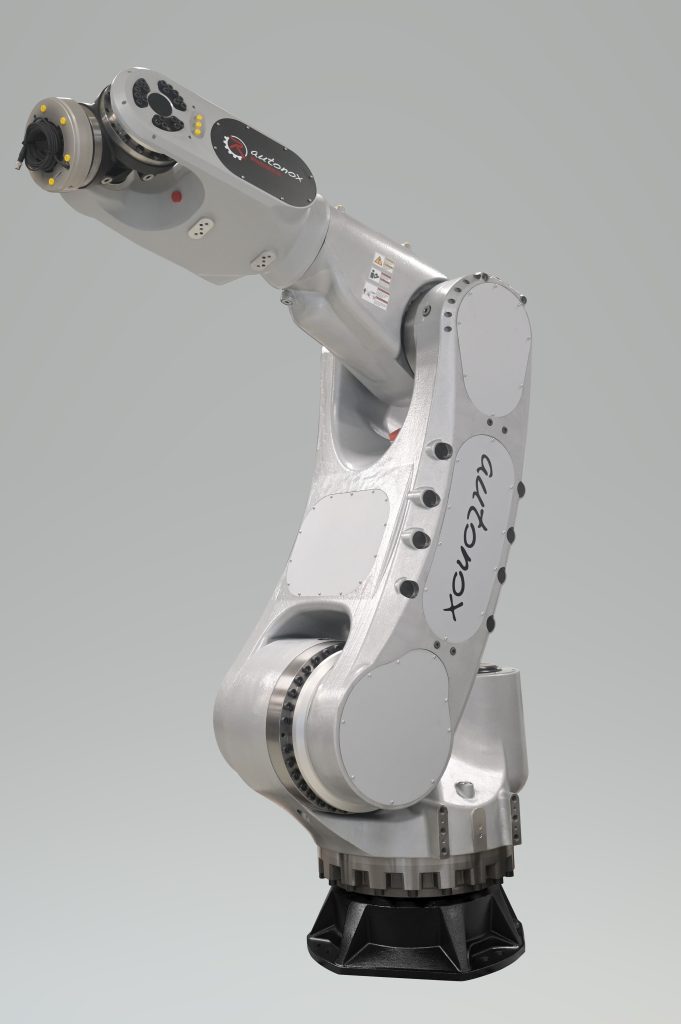

autonox Robotics: A proven partner for innovative solutions

autonox Robotics is a long-standing partner in the Sinumerik Run MyRobot ecosystem. The company is known for its powerful and reliable robotic solutions that are used in numerous industries worldwide. autonox offers its customers more accurate and efficient machining solutions using dedicated CNC robotic mechanisms.

Danobat: A new player in the high-precision CNC robotics market

Danobat is an internationally active consortium and a new Siemens partner. It offers MTR robots ranging from a compact version with a payload capacity up to 220 kg and a 2.6 m reach to the most robust model that can handle a payload up to 520 kg with a 3.6 m reach. These robots combine the accuracy and stability of a machine tool with the agility and flexibility of a 6-axis robot, which creates new manufacturing opportunities for demanding industries like aerospace, e-mobility, and energy. Thanks to its partnership with Siemens and the integration of the Sinumerik MTR, Danobat can continue strengthening its position as one of the leading providers of high-precision robotic solutions and tap into new market segments.

The Machine Tool Robot’s innovative technology will be introduced at the JEC and EMO trade show at both the Danobat and the Siemens booths and at the Automatica trade show at the Siemens booth.

Related Story

The Digital Machine Shop — Siemens to Present Digital-Native CNC and More at IMTS 2022

During IMTS 2022, Siemens will present its hardware automation and software technology portfolio, highlighted by the first-ever, digital-native CNC platform, SINUMERIK ONE, for machine tool applications.

In addition, Siemens will present its solutions and services for the industrialization of additive manufacturing. In booths 133346 and 433028, the company will highlight how machine users can quickly and easily embark on their digitalization journeys — from part concept to design, digital twin to simulation, part, and machine production, as well as total integration of these processes into the digital enterprise for job shops and production departments alike.