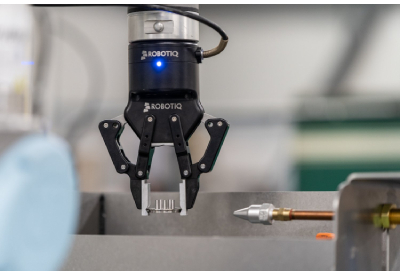

‘Eyes, Hands, Brains and Mobility’ Will Define Robotics Beyond 2025

February 27, 2025

- Building on 50 years of robotics leadership, 2025 marks the beginning of a new era of AI application in industrial robotics.

- New age of Generative AI-powered automation makes robots more intelligent, mobile, accessible and versatile, disrupting new and emerging sectors for robotics.

- Launch of new ABB Robotics brand film unveils new levels of versatilty for robots to do more tasks, in more places.

Having driven analytical AI innovations for over 10 years, ABB has demonstrated that this technology is mature, creating tangible benefits and increasing adoption in industrial automation by overcoming challenges that have previously limited the use of robots in fast-moving, dynamic environments.

“Now using the latest technology, enabled and enhanced by generative AI as well as vision and mobility systems, we are expanding our offering to customers,” said Sami Atiya, President of Robotics & Discrete Automation at ABB. “What if you could work alongside a robot that could not only follow your commands but learn, adapt and move freely through dynamic environments as it takes on new tasks? After our first 50 years of innovation in ABB Robotics, we now turn towards a future where this is a reality in the workplace, lowering the barriers to automation for our customers while helping to increse productivity to build a more prosperous society.”

While global megatrends – from a shrinking labor force, to increasing personalization and the need for sustainable operations – continue to drive demand for the flexibility and resilience provided by automation, a new age of Generative AI-powered automation makes robots even more intelligent, accessible and versatile, disrupting new and emerging sectors for robotics.

“We have already given our robots eyes, through 3D AI vision technology; hands, through advanced force-sensing and dexterity; and independent mobility, through 3D mapping,” said Marc Segura, President of ABB Robotics Division. “ Now, with the quantum leap forward of generative AI, we are driving innovation in their brains, with problem-solving intelligence and the ability to understand our language.

“This capability – to understand our spoken instructions, and work out how to execute tasks, with no prior programming – brings new horizons of versatility to robots to do more things, in more places, and do it faster, safer and smarter. And it opens a door to automation for businesses, without needing specialist skills or infrastructure.

“This new age of versatility will lead robotics deeper into transforming new sectors, from logistics, to construction, healthcare and life sciences and we’re making it possible, today.”

You can watch the brand film here:

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, they call this ‘Engineered to Outrun’. The company has over 140 years of history and around 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB Robotics & Discrete Automation as one of the world’s leading robotics and machine automation suppliers, is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by their value-creating software.

They help companies of all sizes and sectors – from automotive to electronics and logistics – to outperform by becoming more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future, operating leaner and cleaner for a better future. The business area employs approximately 11,000 people at over 100 locations in approximately 53 countries. go.abb/robotics

Related Story

ABB Robotics Introduces AppStudio No-Code Tool for Robot Interface Programming

ABB Robotics has launched AppStudioTM, an intuitive no-code software tool designed to empower users of all experience levels to quickly and easily create customized robotic user interfaces. With intuitive functionality and features including a collaborative cloud-based library enabling users to share application templates, AppStudio will reduce setup times by up to 80 percent.