POSITAL Measuring Wheels: Linear Position and Speed Sensing with Rotary Encoders

March 11, 2024

Easy Configuration & Advanced Programmability with POSITAL’s Measuring Wheel Encoder

POSITAL’s measuring wheels and accessories, combined with the company’s versatile IXARC encoders, can be a convenient and accurate way of measuring linear motion in applications such as conveyer systems or the manufacture of rolled products. Recent enhancements to POSITAL’s programmable encoders have made it simpler to configure wheel-equipped encoders to meet users’ exact requirements.

“Encoders are great for measuring rotation”, comments Andy Zou, Product Manager at POSITAL. “But for many production processes, measurement of linear position or speed is what’s needed. Adding a measuring wheel to an IXARC rotary encoder produces a versatile tool for making these measurements.” Wheel-encoder assemblies measure speed and position directly from a moving surface, avoiding errors due to gear backlash or hysteresis that can arise when encoders are connected directly to rollers or drives. For cut-to-length applications, measuring product position directly from the surface of materials such as fabric, paper, wire, or sheet metal can improve accuracy and reduce scrap losses. POSITAL’s measuring wheel-encoder combinations provide resolutions as fine as 0.1 mm/pulse for all available wheel sizes.

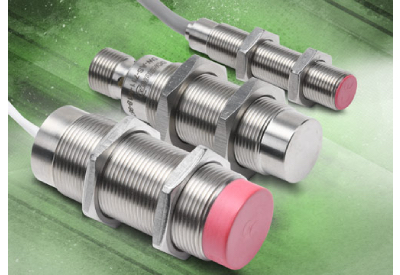

POSITAL’s IXARC incremental encoders – the heart of the wheel/encoder set – are programmable. Resolution is defined by software parameters and can be modified with no changes to mechanical components. Commonly used resolutions, such as 1000, 1024 or 2048 PPR are available, along with resolution as high as 16,384 PPR. Likewise, output drivers can be set to either Push-Pull (HTL) or RS422 (TTL) to ensure compatibility with PLCs. In summary, POSITAL wheel/encoder sets can be customized to meet the exact requirements of each application. And, if production machinery is modified later, wheel/encoder sets can be re-configured on-site through simple software updates.

Measuring wheels are available with circumferences of 200 mm, 500 mm, or 12 inches. Four rim treatments are available: knurled aluminum, smooth polyurethane, and two tread patterns for the polyurethane tire. POSITAL also offers several spring-loaded mounting bracket and pivot arm assemblies designed to minimize slippage by maintaining a steady contact pressure between the wheel and a moving surface. Pivot arms can accommodate large lateral movements and feature adjustable spring tension for optimal contact pressure.

POSITAL’s measuring wheels and mounting accessories, including both individual components and complete assemblies, are listed in the company’s Product Finder portal at www.posital.com. This helps users select the components that are right for their applications.

About POSITAL

POSITAL is a supplier of advanced industrial position sensors used in a wide variety of motion control and safety systems. The company is also an innovator in product design and manufacturing processes and a pioneer of Industry 4.0 (Industrial Internet of Things/IIoT), offering customers the benefits of built-to-order products combined with the price advantages of mass-production.

POSITAL is a member of the international FRABA group, whose history began in 1918, when its predecessor, Franz Baumgartner elektrische Apparate GmbH, was established in Cologne, Germany to manufacture relays. Since then, the company has played a trendsetting role in the development of rotary encoders, inclinometers and other sensor products. POSITAL’s sister company, UBITO, specializes in the development and commercial applications of Wiegand technology, an exciting tool for event sensing and energy harvesting. POSITAL and UBITO have a global reach with offices in Europe, North America and Asia – and sales and distribution partners around the world.

More Information

Related Product

Programmable POSITAL Encoders Updated to Support ‘Fractional PPR’

POSITAL’s IXARC programmable incremental rotary encoders can now be configured to deliver ‘fractional pulse rates’ (fractional PPR). That is, these devices can be programmed to transmit a single pulse for more than one shaft revolution (for example, a PPR of 0.125 would correspond to one signal pulse for eight shaft rotations). They can also be set up to deliver pulse rates that are not even multiples of the number rotations (a PPR of 3.5 would correspond to seven pulses for two rotations).