P2.e Series: Compact Design, High Thermal Limit Performance

August 11, 2025

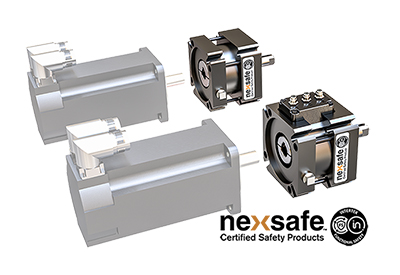

SEW-EURODRIVE’s planetary gear unit product portfolio includes a particularly powerful solution with the P2.e series. Thanks to their compactness, flexibility, and high thermal limit power, these gear units are the ideal choice for continuous-operation heavy-duty applications in confined spaces.

Powerful planetary gears for heavy-duty applications

The P2.e planetary gearbox series is already available in sizes P.002e to P.052e for a torque range from 24.8 kNm to 124 kNm. Starting in August 2025, three additional sizes will be added, achieving rated torques of up to 359 kNm.

As a 2- or 3-stage planetary gearbox, the gear ratio range is 15.2 to 332. The high torque density and the associated compact design enable the gearbox to be used in applications with limited installation space. For simultaneous high thermal performance, there is the option of a fan integrated into the motor interface. The fan draws in radial air, accelerates it, and generates a cooling airflow with high throughput. In addition to the high power density, the P2.e series also boasts a “best-in-class” thermal performance.

The direct mounting of DR.. AC motors from SEW-EURODRIVE eliminates the need for the usual motor adapter flange, making it particularly space-saving. The combinable motors enable finely graduated performance classes and a wide range of options. Furthermore, the modular motor system from SEW-EURODRIVE meets all required efficiency classes and country-specific regulations. An IEC adapter and a NEMA adapter for 60 Hz NEMA motors are also available for mounting stand-alone AC motors.

The P2.e series gear units combine performance and availability with the flexibility of SEW-EURODRIVE’s modular motor system. In tight installation spaces where helical gear units cannot be used, the P2.e planetary gear unit is the optimal drive solution. This opens up new possibilities for customers to optimize their systems.

More Information

Find a location now and get advice!

Related Story

SEW-EURODRIVE USA Now Assembles and Delivers P2.e Planetary Gear Units in Just 6 Weeks

SEW-EURODRIVE has announced a major expansion in its U.S. manufacturing capability with the local assembly of its advanced P2.e planetary gear units, now available with lead times as short as six weeks in 2-stage and 3-stage catalouged ratios and as little as 12 weeks for non-stocked options.

The new domestic assembly capability enables faster project turnaround and delivers on SEW EURODRIVE’s commitment to supporting the North American market with high-performance drive technology, engineered for reliability, flexibility, and sustainability.