MiR Launches Two Powerful Autonomous Mobile Robots to Optimize All Logistics

September 2, 2021

Mobile Industrial Robots (MiR), a major global provider of autonomous mobile robots (AMRs), recently launched its most powerful robots for transporting pallets and other heavy items around manufacturing facilities, warehouses and logistics centers. The MiR600 and MiR1350 robots, which can lift up to 600 kg (1322 pounds) and 1350 kg (2976 pounds), respectively, are designed to safely and efficiently perform material handling tasks in challenging industrial environments.

“Customers testing AMRs within their facilities have learned that they want to transport heavier loads, and that successfully investing in large fleets for core production demands ever greater levels of reliability, safety and quality,” said Søren E. Nielsen, president, Mobile Industrial Robots. ”Our new industrial and robust robots meet these requirements, making them an easy choise to integrate directly into companies’ workflows.”

First IP52-rated AMRs to tolerate common environmental challenges

The industrial and protected MiR600 and MiR1350 are the market’s first Ingress Protection52-rated autonomous mobile robots, which mean their components are protected and can tolerate dust and water drops.

“With AMRs increasingly integrated into core productions, downtime is not an option,” Nielsen said. “Our new AMRs are industry grade and constructed for a long lifetime with easy serviceability thanks to components and cables that are industrial and easy to access.”

New AMRs optimize all logistics—inbound, production and outbound

The larger MiR600 and MiR1350 are ideal for autonomously transporting heavy loads of materials and goods in:

- – loading bays

- – production and assembly areas

- – warehouses

- – material delivery areas

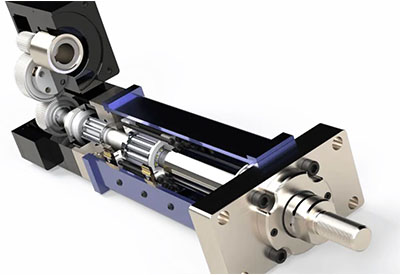

Like MiR’s other AMRs (MiR100, MiR200, MiR250, MiR500 and MiR1000), the MIR600 and MIR1350 navigate smoothly and safely among people and other transport equipment in dynamic surroundings. Sensors, 3D cameras and the latest laser scanning technology ensure 360-degree vision for precise and safe navigation and operations. The new AMRs are designed to comply with the industry’s latest safety standards, e.g. ISO 3691-4.

“Many companies now integrate our mobile robots as an alternative to manned forklifts, which can be expensive to staff and dangerous to operate,” Neilsen said. “The streamlined transport provided by AMRs frees employees to carry out more value-creating activities and support processes in production while they increase shop floor safety.”

Out-of-box solutions to meet demand for scalability and adaptability

Future-proof logistics solutions must fit seamlessly into operational processes and adapt flexibly to new workflows and environments. The AMRs from MiR are highly flexible and can be deployed with different top modules for customized applications.

While many companies ask for adaptable robot platforms, others request out-of-the-box solutions that can be used in multiple types of workflows or diverse customer sites. To ease implementation, MiR offers a number of lift top modules for the MiR600 and MiR1350. These top modules enable the AMRs to pick up and drop off pallets and carts for easy integration and scalability throughout the entire value chain.