igus® Demonstrates Commitment to Innovation and Sustainability at Hannover Messe 2025

May 22, 2025

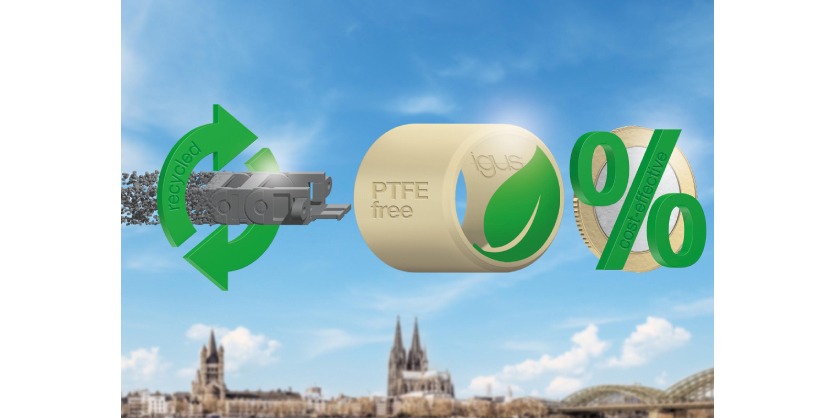

Demonstrating its dedication to innovation and sustainability, igus®presented environmentally friendly technologies at Hannover Messe 2025. The motion plastics specialist will showcase its new PTFE-free materials, cable carriers made from recycled materials and newly developed dry cleanroom certification for its e-chain® cable carriers developed in collaboration with Fraunhofer IPA.

“Our mission remains to provide products ‘made in Germany’ that enhance customer competitiveness while delivering sustainable, cost-effective solutions without compromising quality,” says Michael Blass, CEO of e-chain® systems at igus®.

PTFE-Free Materials

igus® has addressed regulatory changes regarding polytetrafluoroethylene (PTFE) by researching and developing alternative materials. Through extensive in-house testing, these formulations are shown to perform better than traditional PTFE-containing materials. the company has introduced PTFE-free alternatives for its entire range of iglidur® standard materials, which join the company’s PTFE-free and PFAS-tested linear guides, slewing ring bearings and tribotape® liners.

Cable Carriers Made From Recycled Materials

igus® also advances sustainability through its “chainge” recycling program using discarded energy chains, fishing nets and other recycled materials. After successfully introducing a recycled energy chain in 2022, the company is transitioning its entire E2.1 series to the recycled material — a development that reduces the carbon footprint by roughly 80% without compromising mechanical specifications or increasing costs.

“Through this recycled series, we empower our customers to actively participate in the plastics circular economy,” says Blass.

Dry Cleanroom Certification

In response to growing demand for electric vehicle (EV) batteries, igus® has collaborated with Fraunhofer IPA to establish a long-term cleanroom certification for its products. The E6.29 e-chain® — previously certified for cleanroom applications — has successfully maintained its performance, with the e-skin® soft SKS28 achieving ISO Class 4 after 15 million double strokes and ten months of testing. The E6 energy chain has also retained high performance.

Hannover Messe 2025 attendees are encouraged to visit igus® in Hall 6, Stand E26 to explore these innovative and sustainable motion plastics solutions.

About igus®

igus GmbH develops and produces motion plastics. These self-lubricating, high-performance polymers improve technology and reduce costs wherever things move. In energy supplies, highly flexible cables, plain and linear bearings, and lead screw technology made of tribo-polymers, the company is the worldwide market leader. The family-run company based in Cologne, Germany, is represented in 35 countries and employs 4,600 people across the globe. In 2023, they generated a turnover of €1.136 billion.

Research in the industry’s largest test laboratories constantly yields innovations and more user security. Two hundred 234,000 articles are available from stock, and service life can be calculated online. In recent years, the company has expanded by creating internal startups, for example, ball bearings, robot drives, 3D printing, the RBTX platform for Lean Robotics, and intelligent “smart plastics” for Industry 4.0. Among the most significant environmental investments are the “chainge” program – recycling used e-chains and participating in an enterprise that produces oil from plastic waste.

More Information

Related Story

igus to Exhibit Cutting-Edge Engineering and Automation Solutions at IMTS 2024

igus®, a global leader in motion plastics, is excited to announce its participation in the International Manufacturing Technology Show (IMTS) 2024. The event will be held from September 9-14, 2024, at McCormick Place in Chicago, IL. This year, the company will showcase its latest advancements at two booths, highlighting its commitment to improving motion and automating factories efficiently and cost-effectively.