Fiix by Rockwell Automation Announces Industry-Leading GenAI Prescriptive Work Orders

May 2, 2024

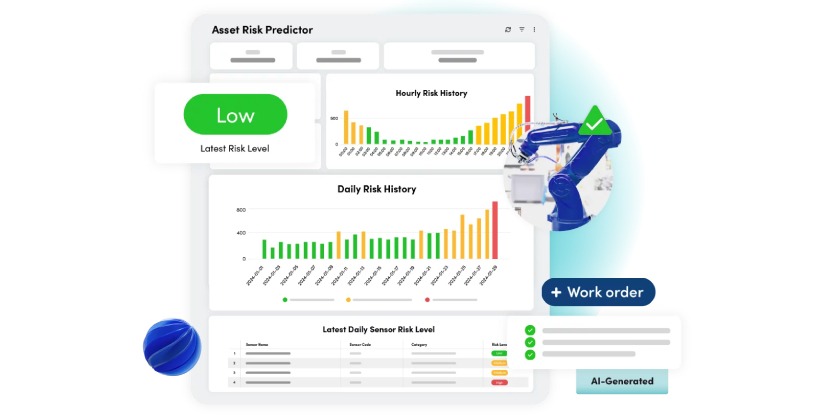

Included in Fiix Asset Risk Predictor, Fiix Prescriptive Maintenance transforms asset health predictions into actionable work orders

Rockwell Automation, Inc., one of the world’s largest companies dedicated to industrial automation and digital transformation, is excited to add cutting-edge, generative artificial intelligence (GenAI) prescriptive work orders to Fiix Asset Risk Predictor software, creating the first complete predictive and prescriptive maintenance solution to help manufacturers eliminate unplanned downtime.

Fiix Asset Risk Predictor’s powerful AI can be set up in as little as two weeks and starts predicting asset failures days in advance. With the addition of Fiix Prescriptive Maintenance, it now features GenAI capabilities that transform failure predictions into detailed, actionable work orders for maintenance teams. Work orders are generated using asset data, completed work orders and trusted maintenance sources. Teams can then review and edit work orders, and instantly push them to any computerized maintenance management system (CMMS) or enterprise asset management (EAM) tool. All data is kept completely private and protected by the highest security standards.

“With Fiix Prescriptive Maintenance, you can turn asset data into the predictions and work orders you need to drastically reduce unplanned downtime, boost operational equipment effectiveness (OEE), and make better use of resources,” says Sandy D’Souza, senior director sales, Americas, Fiix by Rockwell Automation.

“It also helps close the maintenance knowledge gap, ensuring everyone has access to detailed asset and work order information, whether they’ve just started their career or have decades of experience at a company.”

By bringing together AI-powered predictive maintenance and actionable GenAI work orders, Fiix Asset Risk Predictor ensures manufacturers see results in the fastest time possible.

Fiix Asset Risk Predictor, now including Fiix Prescriptive Maintenance, can be purchased and used independently from the Fiix CMMS or seamlessly integrated with it. It can also be integrated with any CMMS or EAM your company uses.

More Information

To learn more about Rockwell’s Fiix Asset Risk Predictor, visit: www.fiixsoftware.com/arp

Related Story

Rockwell Automation to Increase Scale and Scope of AI in Manufacturing with NVIDIA

Rockwell Automation has announced it is collaborating with NVIDIA to accelerate a next-generation industrial architecture.

Manufacturing is a $15-trillion global industry that touches everything humans need to survive and thrive—from clean water to food, life-saving drugs and therapies, sustainable energy, mobility, and more. The company plans to evolve the industry by creating the factory of the future, making it easier for automation customers to digitalize industrial processes. Factories of the future will be characterized by enhanced sensing capabilities with machine vision, accelerated compute capability in control systems, advanced simulations equipped with learning agents, widespread adoption of autonomous mobile robots (AMRs), and generative AI (GenAI) experiences to enhance information retrieval for frontline operators.