Precise FAULHABER Drives for Humanoid Robots

November 24, 2025

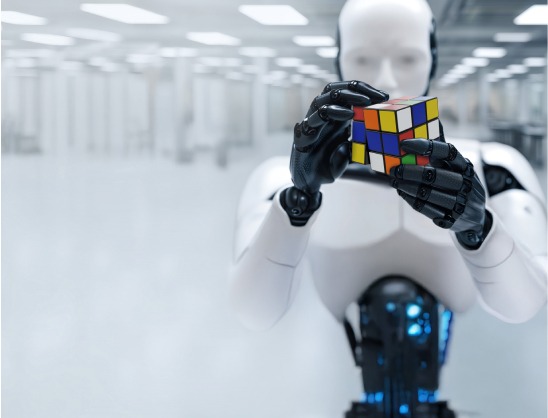

They walk, grip, balance – and fascinate with their human-like appearance: Humanoid robots have impressive mobility and are even able to interpret facial expressions or understand language. What was still a futuristic vision just a few years ago is today taking concrete shape. Hidden behind the technological developments of humanoid robots is a complex interaction of artificial intelligence, precision mechanics and powerful drive technology. Miniaturization plays a decisive role here, as it enables compact designs with high functionality. The contribution of FAULHABER and the use of modern technologies are setting the course for the next stage in the evolution of robotics.

Walking on two legs is a complex matter that must be precisely controlled. Even humans need a good year before this apparently trivial sequence of movements is mastered and the interaction of approximately 200 muscles, numerous complicated joints and various specialized regions of the brain functions. Due to the unfavorable lever ratios for humanoid robots, a motor with minimal dimensions must produce the highest possible torque in order to be able to replicate a human-like movement.

While classic robots are typically used in highly structured environments such as industrial manufacturing or logistics, humanoid robots enter a completely new terrain: daily life. They need to orient themselves in unstructured environments in which, e.g., no living room is like the other and every task is individual. When in direct contact with people, they operate less abstractly but are rather physically present – often within close proximity.

Humanoid robots form the interface between artificial intelligence and the real, physical world. They are able to process not only digital information but also transform this into concrete actions. If the sequences of movements function smoothly and safely, humanoid robots can perform a number of tasks that were previously reserved for humans – be it in hazardous environments, in direct contact with people or in repetitive processes. They assist in the household, support with rehabilitation, interact with older people or are used in retail business. Their strength is in their versatility and ability to adapt to human environments.

The role of drive systems

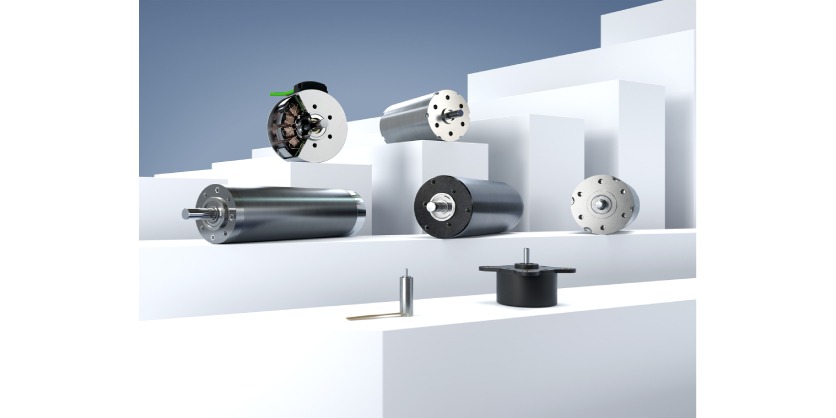

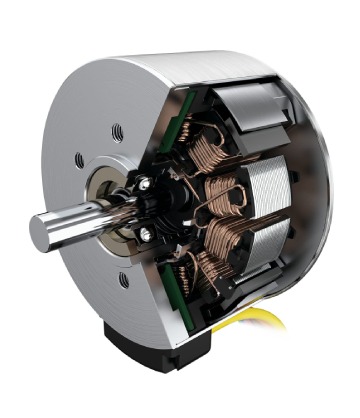

At the core of every movement performed by a humanoid robot is a precise drive system. It decides how smoothly an arm is raised, how quickly a leg can respond or how gently a finger grips. Drive technology thereby has a significant impact on the performance, naturalness and safety of humanoid movements. The miniaturization, energy efficiency, dynamics and precision are central requirements here – an interaction that can be realized only with highly developed micromotors. These are all aspects that are decisive not only in robotics but also in prosthetics.

The transition between humanoid robots and prosthetics is a seamless one. Modern prosthetics – especially arm or hand prosthetics – replicate the movements of the human body and use principles similar to those of humanoid robots to do this. Electromotors, sensors and precise control enable intuitive and forceful movements. Decisive in both cases is the perfect symbiosis of technology and biology – be it for the expansion of human capabilities or to replace lost functions.

FAULHABER for the future of humanoid systems

Micromotors are used not only in humanoid robots but have also long found application in robotized aids such as motorized hand and leg prosthetics. This is shown: They satisfy the highest requirements in especially sensitive and demanding applications. FAULHABER develops and manufactures high-precision drive systems that are installed worldwide in both modern prostheses and in humanoid robots. Whether for delicate finger movements or powerful stepping motions – the motors enable maximum mobility in the smallest of spaces.

This is especially advantageous in dynamic movements that are necessary for replicating human gestures. Particularly as these systems are increasingly interacting directly with people, safety aspects and excellent controllability play a key role. The development of suitable concepts is essential for enabling a smooth and – above all – safe cooperation between man and machine. This is not just a question of the software control – protective mechanisms must also be integrated in the drive solution itself.

FAULHABER takes this need into account with drive solutions that are both powerful and compact as well as designed for safety – ideal for demanding tasks in robotics and medical technology. In practice, this enables even brief, extreme loads without affecting the service life of the components. The close collaboration with leading research institutes and development partners ensures that FAULHABER technology always remains on the cutting edge.

More Information

Precise drives for humanoid robots